I-Hardware yokunyathela ingxenye enomumo othile, usayizi kanye nokusebenza okutholwe ngenqubo yokugxiviza.I-hardware yokugxiviza isetshenziswa kabanzi ku-aerospace, imoto, ukwakha imikhumbi, imishini, amakhemikhali neminye imikhakha, futhi kancane kancane isiyingxenye ebalulekile yomkhakha wamanje wokukhiqiza izingxenye.Inqubo yokugxiviza ithintwa yizici ezintathu: uhlobo lwemishini, impahla yokusebenza kanye nokusebenza kukawoyela.Okulandelayo isingeniso esifushane sezinkinga ezivamile zenqubo yokugxiviza izingxenye zehadiwe yi-MINGXING Petrochemical:

1. Izinzuzo zobuchwepheshe zokugxiviza kwensimbi

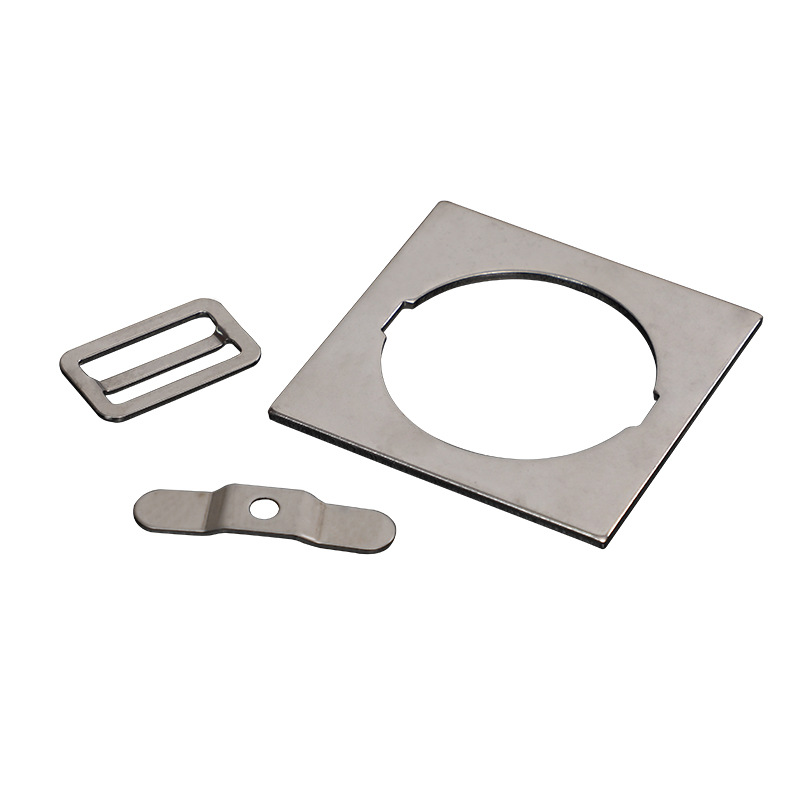

(1) Izingxenye zokugxiviza zensimbi zenziwa ngokugxiviza endaweni yokusetshenziswa kwedatha okuphansi.Izingxenye zabo zilula ngesisindo futhi zinhle ngokuqina.Ngemuva kokuthi insimbi yeshidi idlule ekuguqulweni kwepulasitiki, ukuhlelwa kwesakhiwo ngaphakathi kwensimbi kuyathuthukiswa, futhi amandla ezingxenye zokugxiviza ayathuthukiswa.

(2) Izingxenye zokugxiviza zezingxenyekazi zekhompuyutha zinokunemba okuphezulu kobukhulu, izilinganiso ezifanayo nezivamile zemojula efanayo, nokushintshashintsha okuhle.Idivayisi evamile kanye nezidingo zohlelo lokusebenza zinganeliswa ngaphandle kokwenza imishini.

(3) Phakathi nenqubo yokugxiviza, ngenxa yokuthi ukubukeka kwedatha akukonakali, kunekhwalithi enhle yokubukeka nokubukeka okuhle, okunikeza izimo ezilula zokudweba kwendawo, i-electroplating, i-phosphating nokunye ukwelashwa kwendawo.

2, Ukukhetha Material of metal stamping

Kunezinqubo ezintathu eziyinhloko zokugxiviza: ukuvala, ukugoba nokwelula.Izinqubo ezahlukene zinezidingo ezahlukene zamapuleti.Ukukhethwa kwezinto zokwenziwa kufanele futhi kucatshangelwe ngokuvumelana nokuma okulinganiselwe kwemikhiqizo kanye nobuchwepheshe bokucubungula.

(1) Ukungasho lutho kudinga ukuthi ipuleti libe neplastikhi eyanele ukuze kuqinisekiswe ukuthi ipuleti aliqhekeki ngesikhathi lisikwa.Impahla ethambile inokusebenza okuhle kokungenalutho, futhi ucezu lokusebenza olunesigaba esibushelelezi kanye nokuthambekela okuncane kungatholakala ngemuva kokuvala;Izinga lezinto eziqinile ngemuva kokuvala alilungile, futhi ukungalingani kwesigaba kukhulu, ikakhulukazi kumapuleti aminyene.Ngezinto eziqinile, ukudabuka kulula ukwenzeka ngemva kokuvala, ikakhulukazi uma ububanzi buncane kakhulu.

(2) Amapuleti azogotshwa azoba nepulasitiki eyanele kanye nomkhawulo wesivuno esincane.Ipuleti elinepulasitiki eliphakeme akulula ukuqhekeka lapho ligoba.Ipuleti elinomkhawulo wesivuno esiphansi kanye ne-modulus enwebekayo ephansi inokuguqulwa okuncane kwe-rebound ngemva kokugoba, futhi kulula ukuthola umumo wokugoba ngosayizi onembile.Impahla enokuqina okukhulu kufanele ibe nerediyasi yokugoba ekhudlwana lapho igoba, ngaphandle kwalokho kulula ukuqhekeka ngesikhathi sokugoba.

(3) Umdwebo weshidi lensimbi, ikakhulukazi umdwebo ojulile, ungenye yezingxenye ezinzima kakhulu ohlelweni lokucubungula insimbi.Akudingi nje kuphela ukuthi ukujula komdwebo kube kuncane ngangokunokwenzeka, ukuma kube lula futhi kube bushelelezi ngangokunokwenzeka, kodwa futhi kudinga ukuthi impahla ibe ne-plasticity enhle, ngaphandle kwalokho kulula kakhulu ukubangela ukuhlanekezela okuphelele kwengxenye, yendawo. ukushwabana, ngisho nokuqhekeka okuqinile kwengxenye yomdwebo.

3, Ukukhethwa kwamafutha okugxiviza kwensimbi

Uwoyela wokugxiviza udlala indima ebalulekile enqubweni yokugxiviza, futhi ukusebenza okuhle kokupholisa kanye nokucindezela okwedlulele nokusebenza okungahambisani nokugqokwa kwenze ikhwalithi yokuphila yokuphila kwesevisi yefa kanye nokuthuthukiswa kokunemba kocezu lokusebenza.Ngokusho kwezinto ezihlukene ze-workpiece, ukusebenza kwamafutha okugxiviza nakho kuhlukile uma ukhetha.

(1) Ipuleti lensimbi ye-silicon liyinto elula uma ishaywa.Ngokuvamile, ngenjongo yokuhlanza i-workpiece, amafutha okubhoboza ama-viscosity aphansi azokhethwa endaweni yokuvimbela ukubhoboza i-punching burr.

(2) Lapho ukhetha uwoyela wokugxiviza we-carbon steel plate, i-viscosity engcono izonqunywa ngokuvumelana nobunzima benqubo, indlela yokudweba ukunikezwa kukawoyela kanye nokunciphisa amafutha.

(3) Ngenxa yokusabela kwamakhemikhali phakathi kweshidi lensimbi elinamandla nezithasiselo ze-chlorine, kufanele kuqashelwe ukuthi kungenzeka ukugqwala okumhlophe kohlobo lwe-chlorine uwoyela wokunyathela lapho kukhethwa uwoyela wokugxiviza weshidi lensimbi, kanye nokusetshenziswa kwe-MINGXING sulfur type stamping. uwoyela ungagwema inkinga yokugqwala, kodwa kufanele wehliswe amafutha ngokushesha ngangokunokwenzeka ngemva kokugxiviza.

(4) Ipuleti lensimbi engagqwali liwumsebenzi okulula ukuwenza lukhuni, ngakho-ke kuyadingeka ukusebenzisa amandla efilimu kawoyela aphezulu kanye namafutha aqinile e-anti-sintering.Ngokuvamile, uwoyela wokugxiviza oqukethe izithasiselo ezihlanganisiwe zesulfure ne-chlorine usetshenziselwa ukuqinisekisa ukusebenza kwengcindezi eyedlulele futhi ugweme i-burr, i-crack nezinye izinkinga ze-workpiece.

Lezi yizici ezithinta ikhwalithi yezingxenye zokunyathela zensimbi.Ngokuthuthuka okusheshayo kobuchwepheshe bokugxiviza ngokunemba, izingxenye ezincane zokugxiviza zingahlangabezana nezidingo zezinhlobo ezahlukene zamathuluzi omshini, izinto zikagesi, izinsimbi nezinye izimboni zokukhiqiza.I-MINGXING iyisisekelo socwaningo nentuthuko yezinsizakusebenza zensimbi ezisezingeni eliphezulu.Amafutha okugxiviza athuthukiswe ngokuzimela anokucindezela okukhulu kakhulu nokusebenza okungahambisani nokugqoka, angavikela ngempumelelo ukufa, athuthukise kakhulu ukusebenza kahle, futhi andise impilo yesevisi yemishini.Inguzakwethu oqokiwe wamabhizinisi amaningi emishini yemishini emikhulu namaphakathi e-China, futhi izuze ukuqashelwa okubanzi nokunconywa okuphezulu embonini.

Isikhathi sokuthumela: Feb-16-2023