Ukugxiviza kuyinqubo yokwakha encike ekunyatheliseni futhi kufa ukuze kusetshenziswe amandla angaphandle kumapuleti, amapheshana, amapayipi kanye namaphrofayili ukukhiqiza ukuguqulwa kwepulasitiki noma ukuhlukaniswa ukuze kutholakale izingcezu zokusebenza zomumo nosayizi odingekayo.Ngokwemibandela yenqubo ehlukene, inqubo yokugxiviza inezindlela ezihlukene zokuhlukanisa.Ake sethule kafushane ukuthi yiziphi izinhlobo zeinsimbiinqubo yokunyathelakokulandelayo.

1.Ngokwe-workpiece eqediwe ukuhlukaniswa:

Inqubo yokugxiviza ingahlukaniswa izigaba ezimbili ngokuya ngocezu lokusebenza oluqediwe: inqubo yokuhlukanisa kanye nenqubo yokwenza (futhi ihlukaniswe ngokugoba, ukudweba kanye nokwakha).

2.Ngokwezinga lokushisa kweukunyathelaukuhlukanisa:

Kunezinhlobo ezimbili zokugxiviza, ukugxiviza okubandayo kanye nokugxiviza okushisayo, ngokusho kwesimo sokushisa ngesikhathi sokunyathela.Lokhu kuncike emandleni, i-plasticity, ukujiya, izinga lokuguquguquka kanye nomthamo wemishini yezinto ezibonakalayo, njll. Isimo sokuqala sokwelashwa kokushisa kwezinto kanye nezimo zokugcina zokusetshenziswa kufanele futhi kucatshangelwe.

3. Ukuhlukaniswa ngokwesakhiwo se-ukufa ngesibhakela:

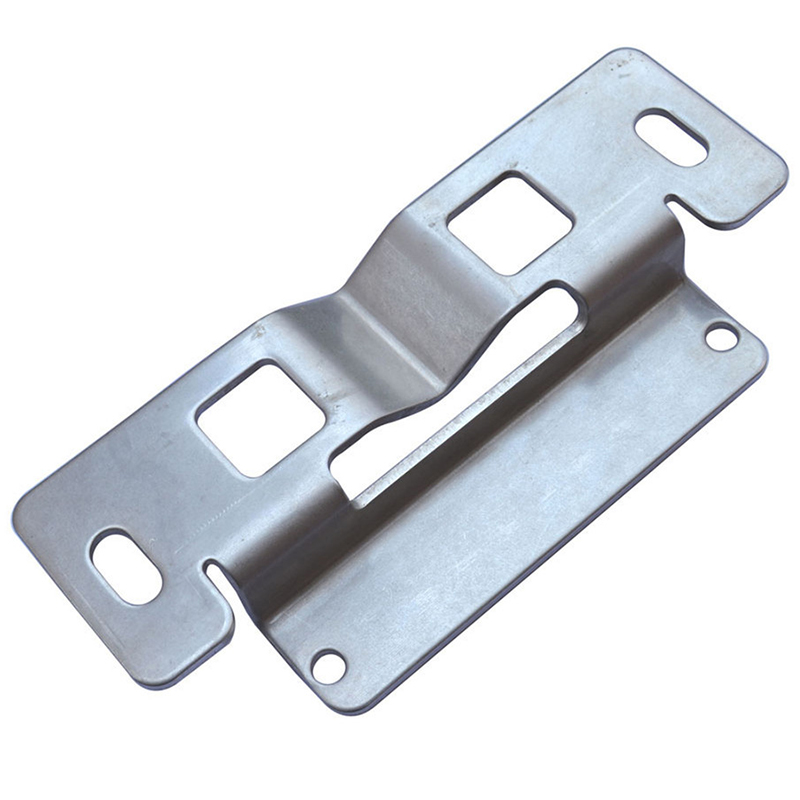

I-punching die iyithuluzi lokukhiqiza ukuhlukaniswa noma ukuguqulwa kwempahla yeshidi, equkethe izingxenye ezimbili: i-die engenhla kanye ne-die ephansi.Idayi engenhla igxilwe kusilayidi somshini wokubhoboza futhi yehla naphezulu ngesilayidi, kuyilapho idayizi engezansi igxilile etafuleni lomshini wokubhoboza.Kuwukufa okubalulekileukukhiqizwa kwezitembu.Ngokwesakhiwo se-die, inqubo ingahlukaniswa ibe isitembu esilula, isitembu esiqhubekayo kanye ne-compound stamping.

4. Ukuhlukaniswa ngokwezinqubo eziyisisekelo:

Ngokwenqubo eyisisekelo ukugxiviza kuhlukaniswe ngezinqubo ezimbalwa eziyisisekelo ezifana nokuwa, ukubhoboza, ukugoba nokudweba okujulile.

5. Ukuhlukaniswa ngokwezinto zokugxiviza isitembu somsebenzi:

Amapuleti asetshenziswa kakhulu yi-titanium alloy ephansi, i-carbon steel, insimbi engagqwali, i-aluminium, ithusi nama-alloys ayo, njll. Ane-plasticity ephezulu kanye nokumelana okuphansi kwe-deformation, futhi afaneleka ukucubungula isitembu esibandayo.

Isikhathi sokuthumela: May-29-2023