Isistimu yebhethri yamandla ibhekisa kuidivayisi yokugcina amandlasesetshenziselwa ukuhlinzeka amandla ekushayeleni imoto kagesi futhi iqukethe iphakethe lebhethri elilodwa noma amaningi kanye abms uhlelo lokulawula.Ukuthembeka nokuhlala isikhathi eside kwephakethe lebhethri lamandla, umgogodla wemoto kagesi emsulwa, ukhiye wobubanzi bomucu we-nickel.Impahla yelinye lamathebhu okuxhuma amaseli amandla ingenye yezinto ezibalulekile ezithinta ukusebenza kwephakethe lebhethri.Imodyuli yebhethri yamandla ihlanganiswe ngamaseli amaningana angashadile ochungechungeni futhi ahambisanayo, futhi uxhumano nokuqiniswa phakathi kwamaseli angashadile kudinga ukumelana nokuxhumana okuncane, ukumelana nokudlidliza nokuthembeka okuphezulu phakathi kwesiqephu sokuxhuma nesigxobo sebhethri.Ngakho-ke ungakhetha kanjani i-bms ibhethriokokusebenza kwesixhumi ukuqinisekisa ukuthi ukusebenza kwebhethri kukhulu?

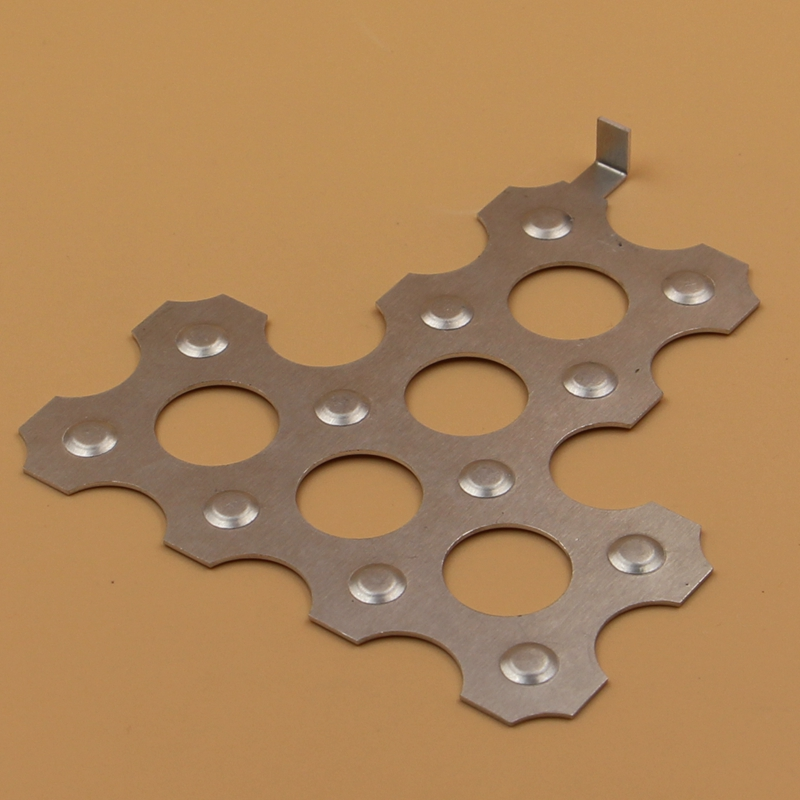

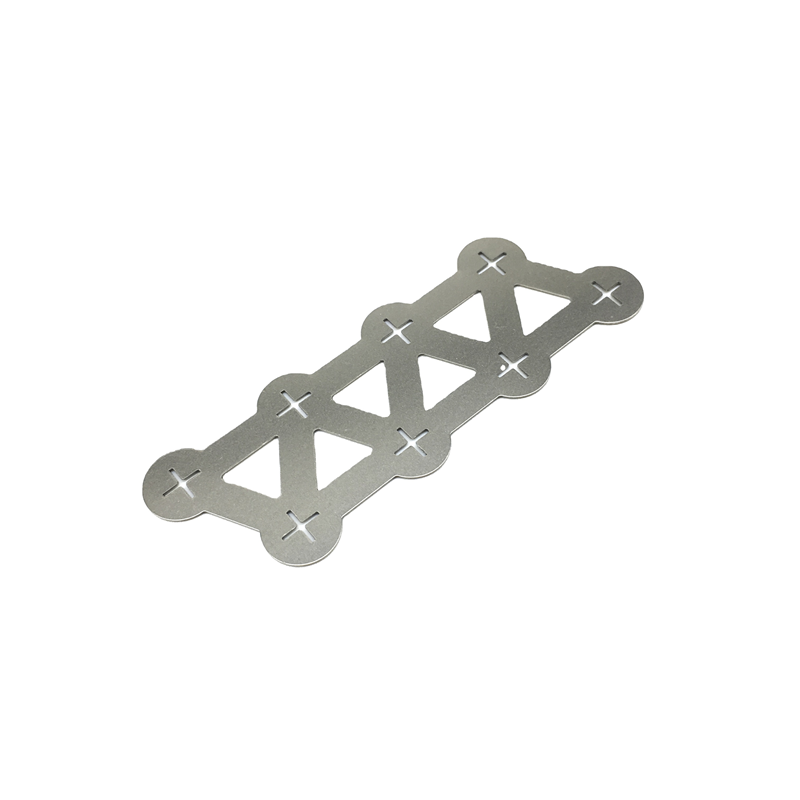

Izixhumi zebhethri ngokuvamile ziyi-trapezoidal, unxande, unxantathu futhi umumo wesigaba.Kungakhathaliseki ukuthi nge-laser welding, ukumelana ne-welding noma ukukhiya ngomshini we-bolt, kuyadingeka ukuqinisekisa ukwethembeka nokuqina kweuhlelo lwebhethrienqubweni yangempela yokushayela yezimoto zikagesi, ibhande lensimbi eline-nickel-plated linokuqukethwe okuphezulu kwe-nickel, elinezinga elithile lebhande / ishidi lensimbi engagqwali kazibuthe kanye ne-corrosion, elinokumelana ne-oxidation, ukumelana nokugqwala, izakhiwo ezinhle kazibuthe, ipulasitiki enhle, ukuphakama kwe-nickel kuhlanzekile, kuncane ukumelana, akulula ukugqwala.Nezinye izici.Yiqiniso, ucezu lokuxhuma kwebhethri kungenzeka ukusebenzisa ithusi, futhi uthi ukuqhutshwa kwethusi kungcono kune-nickel, ithusi kuzo zonke izinto zensimbi, ukuqhutshwa kwayo kagesi okwesibili kuphela kwesiliva.Kodwa ithusi has a kusimo, kulula nge-oxidation emoyeni.Uma ukhetha ithusi ukwenza ucezu lokuxhuma, idinga ukwenza ukwelashwa kwendawo, okungukuthi, i-nickel plating.I-nickel strip/ishidi lizovimbela ithusi ukuthi lingabi ne-oxidizing.

Mayelana nezindleko zokukhiqiza zezinkampani, ishidi le-nickel libiza ngaphansi kwethusi, lithambile kunethusi, futhi liqinile kunethusi.I-Copper nickel plating yinhle, kodwa isetshenziswa kancane.Okwesibili, umugqa we-nickel omsulwa, iningi lamabhethri omakhalekhukhwini wegama lomkhiqizo asebenzisa umugqa we-nickel omsulwa, kodwa intengo iyabiza.

Kusukela esakhiweni sokuxhuma kanye nenqubo, ye-welding kagesi, i-nickel-plated tape ibuye ibe lula ukushisela, ukumelana nokuxhumeka kwe-welding kungaphansi kokuxhumeka kwesikulufa, okuyinzuzo ecacile yokushisela.Ngesikhathi esifanayo, ukusebenza kahle kokukhiqizwa kwe-welding kungathuthukiswa.

Kusukela kumikhiqizo yomkhiqizo we-nickel-plated steel strip, ukuhlanzeka kwe-nickel engu-99% ngeke kugqwale eminyakeni engu-20.I-Nickel imelana kakhulu nokugqwala, ikakhulukazi kwisoda ye-caustic, futhi i-nickel ayigqwali ngenani elingaphezu kwama-microns angu-25 ngonyaka kusixazululo esibilayo esingu-50% se-caustic soda.I-Nickel nayo inamandla amahle kanye ne-plasticity, futhi ingakwazi ukumelana nokucubungula okuhlukahlukene kwengcindezi.

Isikhathi sokuthumela: Apr-10-2023