Inkqubo yebhetri yamandla ibhekisa kwiisixhobo sokugcina amandlasesetyenziselwa ukubonelela amandla ekuqhubeni isithuthi sombane kwaye siquka iipakethi zebhetri enye okanye ngaphezulu kunye abms inkqubo yolawulo.Ukuthembeka kunye nobude obude bebhetri yamandla, ingundoqo yemoto yombane ecocekileyo, isitshixo kuluhlu lwe-nickel strip.Izinto eziphathekayo zomnye wamandla okudibanisa i-tabs enye yezinto eziphambili ezichaphazela ukusebenza kwebhetri.Imodyuli yebhetri yamandla ihlanganiswe ngamaseli amaninzi ahlukeneyo kwichungechunge kunye nokuhambelana, kwaye ukudibanisa kunye nokudibanisa phakathi kweeseli enye kufuna ukuchasana koqhagamshelwano oluncinci, ukuxhatshazwa kwe-vibration kunye nokuthembeka okuphezulu phakathi kwesiqwenga sokudibanisa kunye nesibonda sebhetri.Ngoko unokukhetha njani ifayilebms ibhetriisixhobo sokudibanisa ukuqinisekisa ukuba ukusebenza kwebhetri kukhulu?

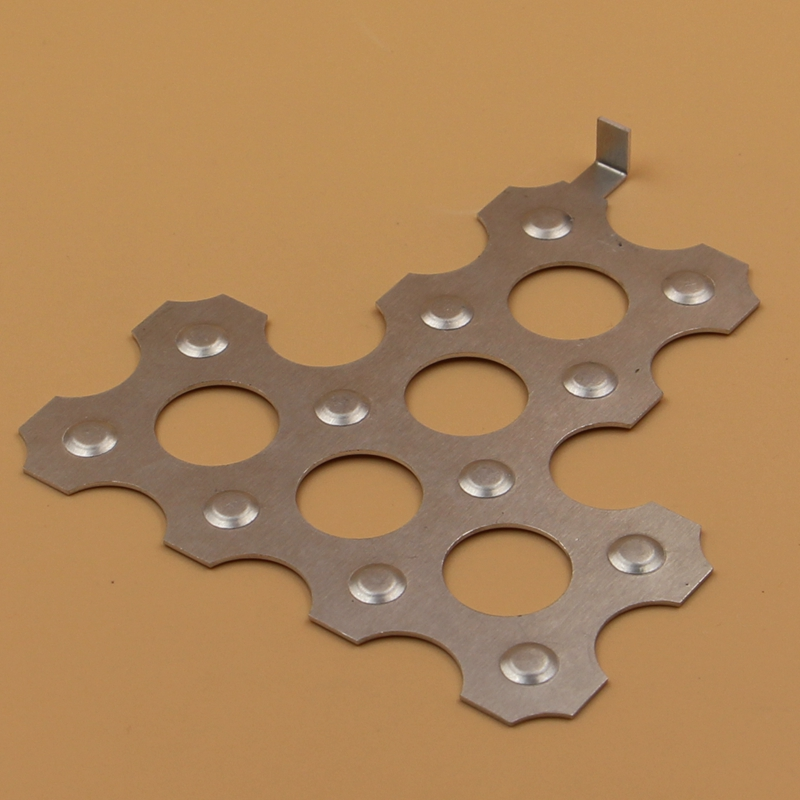

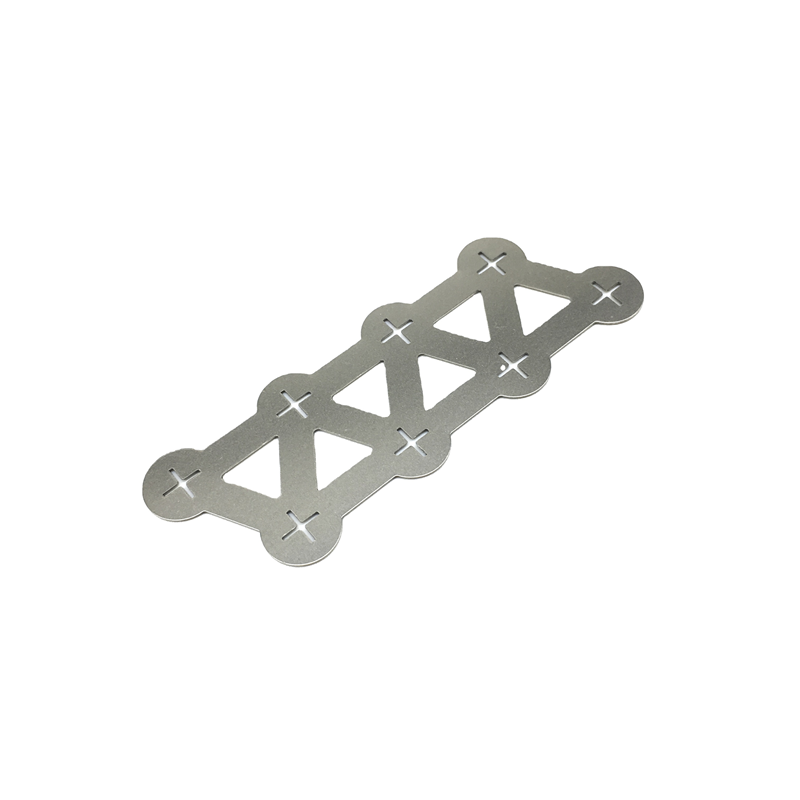

Izixhumi zebhetri ziqhelekile kwi-trapezoidal, uxande, unxantathu kunye nokwakheka kwesigaba.Nokuba nge-laser welding, ukumelana ne-welding okanye ukutshixa ngomatshini, kuyafuneka ukuba kuqinisekiswe ukuthembeka kunye nokuqina kweinkqubo yebhetriKwinkqubo yokuqhubela phambili yeenqwelo zombane, ibhanti yensimbi ye-nickel-plated ngumxholo ophezulu we-nickel, kunye neqondo elithile lebhanti yentsimbi / ishidi ye-magnetic kunye ne-corrosion, enokumelana ne-oxidation, ukumelana nokugqwala, iipropati ezintle zemagneti, iplastiki elungileyo, iphezulu ukucoceka kwe-nickel, incinci ukuchasana, akukho lula ukugqwala.Nezinye iimpawu.Ngokuqinisekileyo, intambo yokudibanisa ibhetri inokwenzeka ukusebenzisa ubhedu, kwaye ithi conductivity yobhedu ingcono kune-nickel, ubhedu kuzo zonke izinto zetsimbi, umbane wayo wesibini wesilivere.Kodwa ubhedu lunento engalunganga, kulula ukwenza i-oxidation emoyeni.Ukuba ukhetha ubhedu ukwenza isiqwenga sokudibanisa, kufuneka senze unyango olungaphezulu, oko kukuthi, i-nickel plating.I-nickel strip / sheet iya kuthintela ubhedu kwi-oxidizing.

Ngokweendleko zemveliso yeenkampani, i-nickel sheet ixabisa ngaphantsi kobhedu, ithambile ngakumbi kunobhedu, kwaye yomelele kunobhedu.I-copper nickel plating ilungile, kodwa isetyenziswa kancinci.Okwesibini, umcu we-nickel ococekileyo, uninzi lweebhetri zeselfowuni zisebenzisa umtya we-nickel ococekileyo, kodwa ixabiso liyabiza.

Ukususela kwisakhiwo soqhagamshelo kunye nenkqubo, kwi-welding yombane, i-nickel-plated tape nayo ilula ukuyidibanisa, ukuxhathisa uxhulumaniso lwe-welding kuncinci kunoxhumo lwe-screw, oluyinzuzo ecacileyo ye-welding.Ngexesha elifanayo, ukusebenza kakuhle kwemveliso ye-welding kunokuphuculwa.

Ukususela kwiipropati zemveliso ye-nickel-plated steel strip, ukucoceka kwe-99% ye-nickel akuyi kugqwala kwiminyaka engama-20.I-nickel ixhathisa kakhulu kwi-corrosion, ngakumbi kwi-caustic soda, kwaye i-nickel ayidli ngaphezu kwe-25 microns ngonyaka kwisisombululo se-50% esibilisayo se-caustic soda.I-Nickel inamandla amahle kunye neplastiki, kwaye inokumelana noxinzelelo oluhlukeneyo.

Ixesha lokuposa: Apr-10-2023