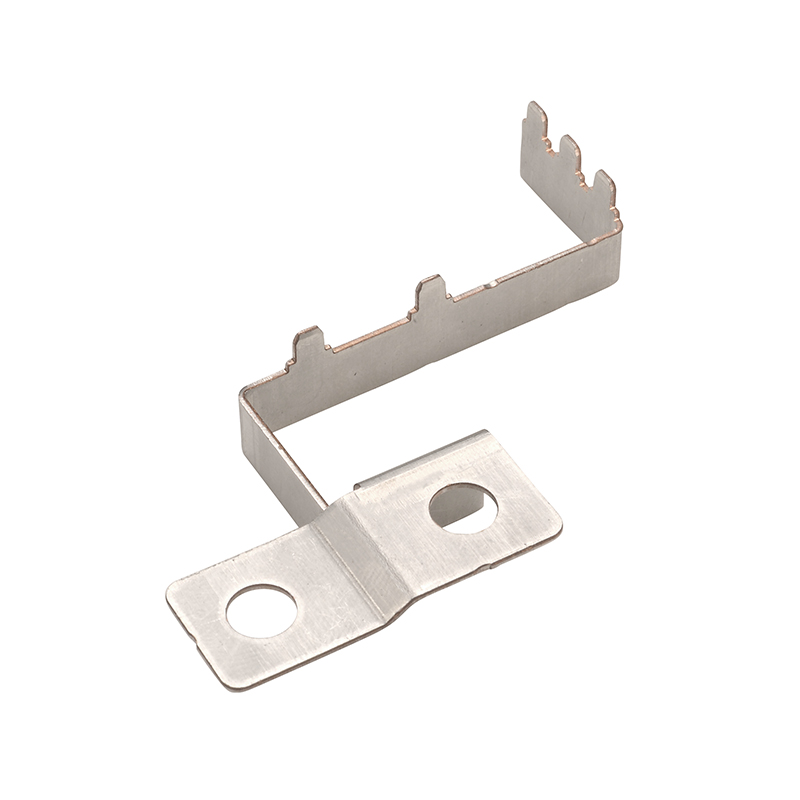

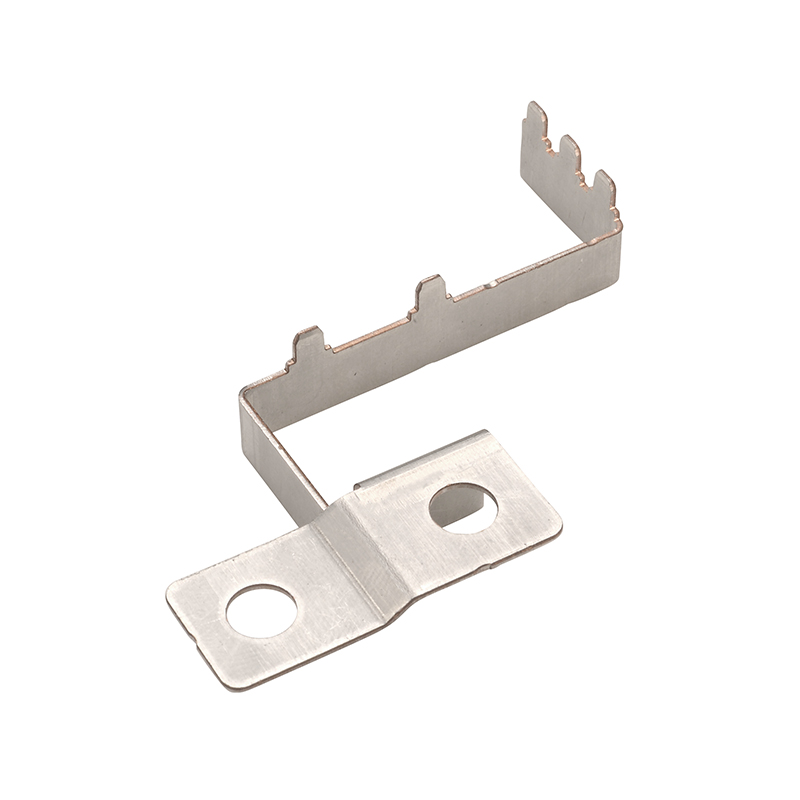

Short Lead Time for Tin Plating Process Flow Chart - Custom Metal Stamping Connection Terminal Spare Parts Electronic Socket Contacts – Mingxing Detail:

Product Description

| Item name | Custom Metal Stamping Connection Terminal Spare Parts Electronic Socket Contacts |

| Material | Copper Alloy, Aluminum Alloy, Stainless Steel, etc. |

| Mold Type | Progressive tool |

| Surface Treatment | Plating, Anodized, Polished, Powder Coated, Painting, etc. |

| Tolerance | as per customers’ requirement |

| Quality Assurance | 100% CCD inspection and QC spot check per 2 hours. |

| Process | Stamping, machining, bending, deep drawing, welding, riveting |

| Mass production | 21 working days for the new mold and within 7 working days for exiting model after receipt of deposit. (Depends on the QTY) |

Custom Stamping Terminal Capabilities

Mingxing is an industry-leading manufacturer of stamped metal parts and assemblies for use in a variety of industries. We’re professional on the manufacture of shielding components designed to block outside electromagnetic energy sources for demanding applications. With many years of production and management experience, our high quality and well-performing shielding cases can ensure your application’s electronic components or systems are safe from electromagnetic interference.

At Mingxing, we can provide full range of services for your custom electronic stamped terminals, which includes:

1.Provide OEM/ODM service.

2.Provide professional metal mould design and manufacturing services.

3.Provide metal parts moulding/ painting services.

4.Provide metal parts assembly service.

FAQ

FREQUENTLY ASKED QUESTIONS

Q1: Are you a direct manufacturer?

A:Yes,we are direct manufacturer.We have been in this domain since 2005. And if you want, we could chatting with you on video via Wechat/Whatsapp/Messenger and any way you like to show you our plant.

Q2: How can you guarantee quality?

A: Always a pre-production sample before mass production;

Always 100% inspection before shipment;

Q3: What kind of service/products you provide?

A: Service of OEM/ one-stopservice/ assembly; From mold design, mold making, machining, fabrication, welding, surface, treatment, assembly, packing to shipping.

Product detail pictures:

Related Product Guide:

We've got a highly efficient group to deal with inquiries from shoppers. Our purpose is 100% client fulfillment by our product high-quality, price tag & our staff service and enjoy a superb reputation amongst clientele. With quite a few factories, we will provide a wide variety of Short Lead Time for Tin Plating Process Flow Chart - Custom Metal Stamping Connection Terminal Spare Parts Electronic Socket Contacts – Mingxing, The product will supply to all over the world, such as: Sheffield, Seychelles, Iran, We accomplish this by exporting our wigs directly from our own factory to you. The goal of our company is to get customers who enjoy coming back to their business. We sincerely hope to cooperate with you in the near future. If there's any opportunity, welcome to visit our factory!!!

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.

-

Best quality Danco Anodizing - Custom CNC Mill...

-

Trending Products Tin Plating Process Pdf - Cu...

-

Hot New Products Copper Bus Bar Fabrication - ...

-

Reliable Supplier Electroplating Diy - Custom ...

-

Wholesale Dealers of Metal Stamping Minnesota -...

-

Manufactur standard Acro Metal Stamping - Cust...