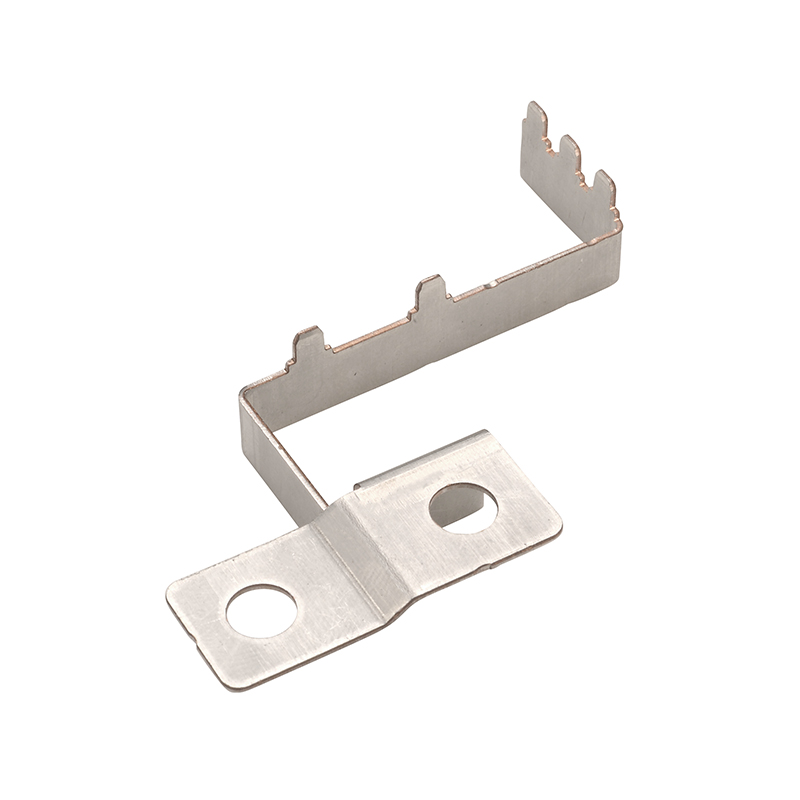

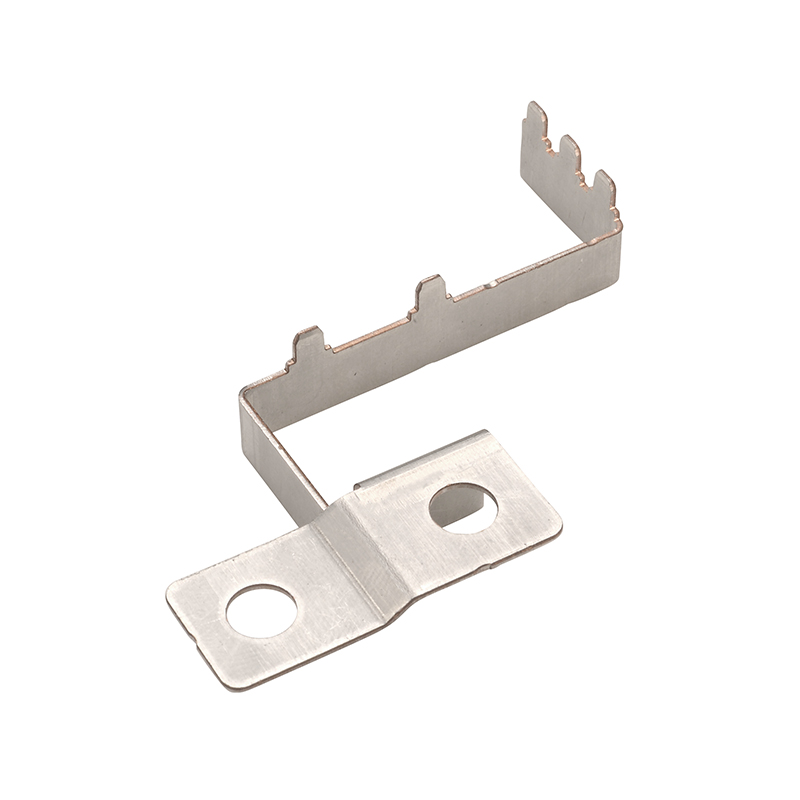

Short Lead Time for Tin Plating Process Flow Chart - China OEM Service Sheet Metal Stamping Part – Mingxing Detail:

|

Material available |

C1100, T2, Bronze, brass, copper alloy, aluminum alloy, tin plated, nickel silver |

|

Surface treatment |

zinc/nickel/chrome/tin plating(colour or natural), Galvanization, anodizing, oil spraying, powder coating, polishing, passivate, brush, wire drawing, painting, etc. |

|

Metal processing available |

Tooling making, Prototype, Cutting, Stamping, Welding, Tapping, Bending and Forming, Machining, Surface treatment, Assembly |

|

Specification |

OEM/ODM, as per client’ s drawing or sample |

|

Certificate |

ISO9001:2015/IATF 16949/SGS/RoHS |

|

Tolerance |

0.02mm-0.1mm |

|

Software |

Auto CAD, Soliworks, PDF |

|

Application |

automotive parts, railroad parts,medical parts, marine parts, lighting parts, pump body, valve parts,architectural parts and furniture parts, etc. |

Metal Stamping

In metal stamping flat metal sheets are fed in the stamping press which is then transformed into different desired shapes. Stamping process is also called pressing. This process includes a number of techniques like punching, blanking, piercing, coining, embossing and so on.

The design for metal stamping has to be precise so that each punch on the metal sheet will result in optimal part quality. Die stamping components can have curved bends and all the bends can be done at once. Progressive die stamping is one of the major techniques used in metal stamping die.

Why choose us?

Mingxing is ITAF-certified and ISO 9001-certified, so our clients can rely on the safety and quality of our stamped products. For over 24 years, our company has designed and manufactured assemblies, custom metal stamping parts, and more. We have well-established facilities dedicated to producing high-quality products with state-of-the-art equipment and the top metal working techniques.

At Mingxing, our capabilities for custom copper busbars includes:

1. RoHS Compliance

2.Barrel and Rack Plating

3. Material Selection Suggestion

4. Progressive Die Stamping

5. Just-in-Time Delivery

6. Design and Assembly

7. Prototyping Services

FAQ

Q: What do you need to provide a quote?

A: It will be worked for us if you have the drawing of the product, we would send you our best offer based on your drawing.

But it is ok for us if you don’t have the drawing, we accept the sample, and our experienced engineer could quote based on your samples.

Q: What is your terms of payment ?

A: 30% paid to start the mass production and 70% balance paid at the sight of copy of B/L.

Q: What will you do for after-service?

A: When our metal parts apply to your products, we will follow-up and await for your feedback.

If need any help of the assembly or other matters, our professional engineer will give you a best solutions.

Q: What delivry can I choose?

A: FOB/CIF/EXW/Express delivery are all avaliable.

Q: How can I get samples?

A: We could offer 10pcs free samples for you to check quality.

Q: What is the MOQ?

A: Usually we don’t set MOQ, but the more, the cheaper. Besides, we are happy to make prototype or sample for clients to ensure quality standa.

Product detail pictures:

Related Product Guide:

We always continually provide you with the most conscientious customer service, and the widest variety of designs and styles with finest materials. These efforts include the availability of customized designs with speed and dispatch for Short Lead Time for Tin Plating Process Flow Chart - China OEM Service Sheet Metal Stamping Part – Mingxing, The product will supply to all over the world, such as: Jamaica, Iran, Czech, We supply skilled service, prompt reply, timely delivery, excellent quality and best price to our customers. Satisfaction and good credit to every customer is our priority. We focus on every detail of order processing for customers till they have received safe and sound items with good logistics service and economical cost. Depending on this, our products and solutions are sold very well in the countries in Africa, the Mid-East and Southeast Asia. Adhering to the business philosophy of ??customer first, forge ahead', we sincerely welcome clients from at home and abroad to cooperate with us.

This enterprise in the industry is strong and competitive, advancing with the times and develop sustainable, we are very pleased to have a opportunity to cooperate!

-

Factory Cheap Hot Chevy Electrical Connectors -...

-

2022 Latest Design Danville Metal Stamping - C...

-

OEM/ODM China Connector Experts - Customized P...

-

Original Factory Zinc Plating At Home - Stainl...

-

Good User Reputation for Metal Stamping For Aut...

-

Massive Selection for Heat Sink Compound - Cus...