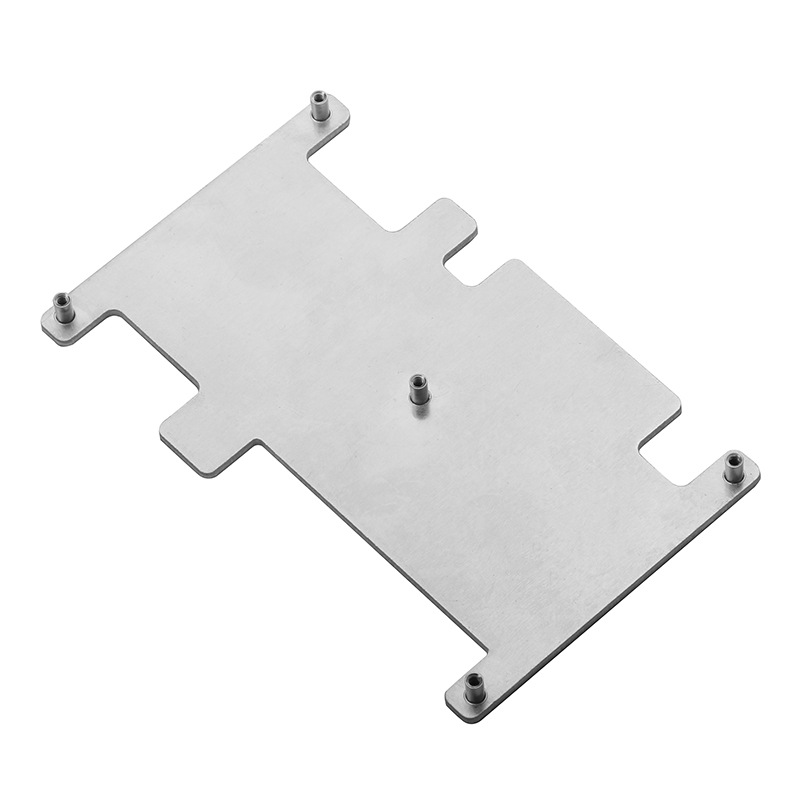

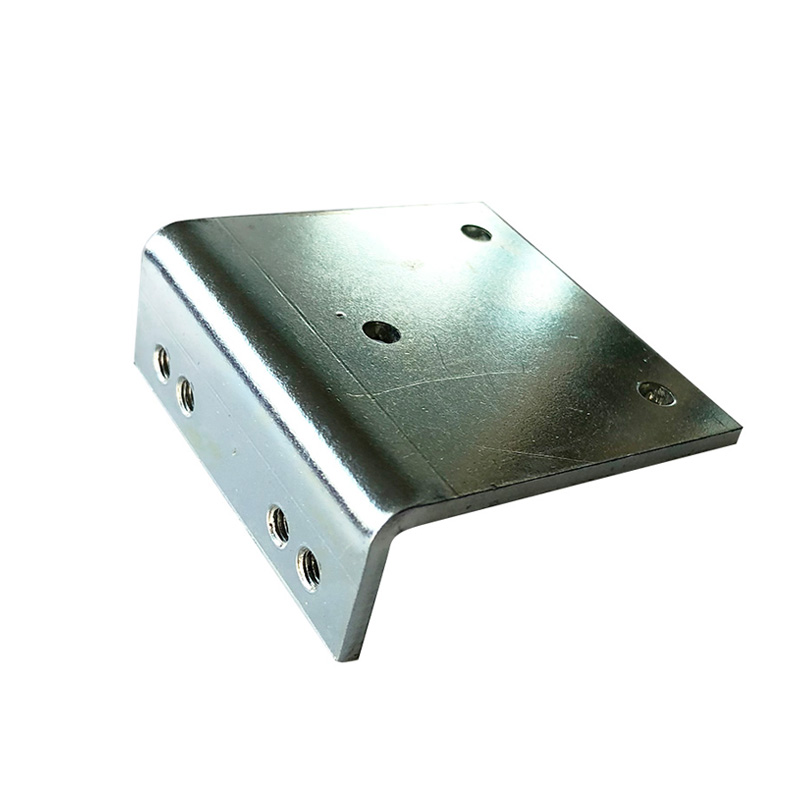

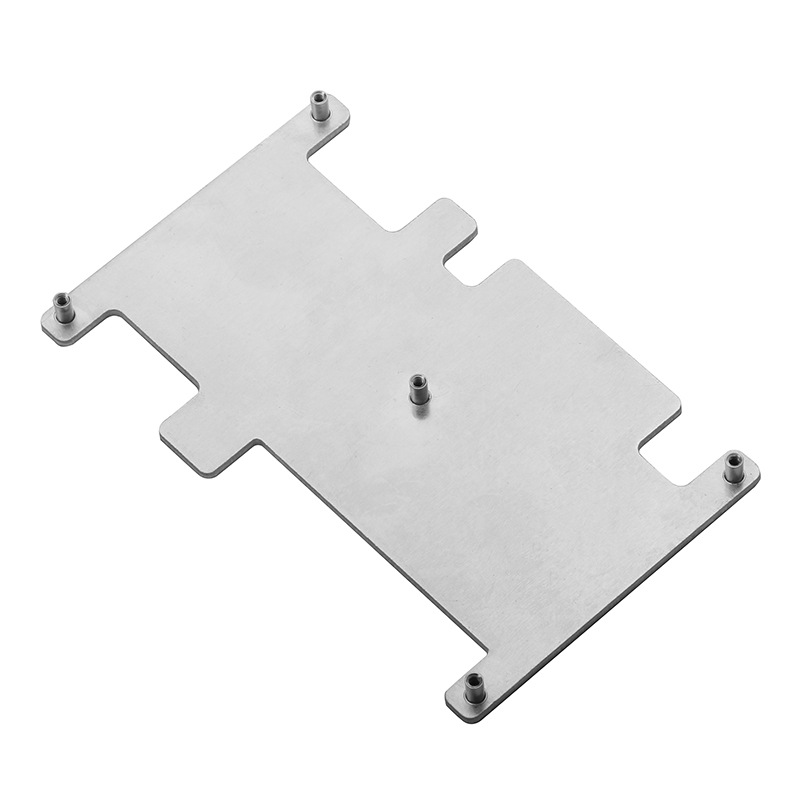

Reasonable price for Standard Copper Busbar Sizes In Mm - Precision Sheet Metal Fabrication Aluminum Bending Stamping Parts Mount Bracket – Mingxing Detail:

Product Description

| Material | Precision Sheet Metal Fabrication Aluminum Bending Stamping Parts Mount Bracket |

| Surface treatment | Carbon steel, SPCC, SGCC, Stainless steel, Aluminum, Brass, Copper, etc. |

| Process | Tooling making, Prototype, Cutting, Stamping, Welding, Tapping, Bending and Forming, Machining, Surface treatment, Assembly |

| Specification | OEM/ODM, as per client’ s drawing or sample |

| Certificate | ISO9001:2015/IATF 16949/SGS/RoHS |

| MOQ | 1000pcs |

| Software | Auto CAD, 3D(STP, IGS, DFX), PDF |

| Application | Automoblies, chassis equipment, furniture accessories, electronic components |

Custom Metal Brackets Capabilities

Our company is IATF-certified and ISO 9001-certified, you can be assured to rely on the safety and quality of the stamped products we produce. We design the brackets strictly as customer’s requirement by CAD and inspected by 24h salt spray test and projector. The manufacturing processes we can be used include stamping, bending, laser cutting, blanking, drilling, lathe and mill, etc.

Our Advantages

1.Professional in producing OEM parts: metal stamped, machined, deep drawn and sheet metal fabricated parts with different surface finishing.

2.20+ years of experience in the metal products processing area and advanced processing machines in saving materials;

3.Reply in time: Reply within 2 hours, TM reply within 30 minutes.

4.100% QC quality inspection before delivery.

5.Delivery on time: two shifts in production.

FAQ

FREQUENTLY ASKED QUESTIONS

Q. Are you a factory or a trade company?

A:We’re a factory with over 20 years experience in the heat sink field.It is a enterprise that professionally design and produce Heat sinks, electronic components, auto parts and other stamping products.

Q. How to get a quotation?

A: Please send us info such as drawing,material surface finish,quantity.

Q. What about the lead time?

A: Average for 12 working days, open mould for 7 days and mass production for 10 days

Q. Do the products of all the colors are the same with same surface treatment?

A: No. about powder coating, the bright-color will higher than white or gray. About the Anodizing, colorful will higher than silver, and black higher than colorful.

Product detail pictures:

Related Product Guide:

With our excellent administration, potent technical capability and strict top quality control technique, we go on to provide our consumers with trusted quality, reasonable price ranges and fantastic providers. We intention at becoming one among your most trusted partners and earning your fulfillment for Reasonable price for Standard Copper Busbar Sizes In Mm - Precision Sheet Metal Fabrication Aluminum Bending Stamping Parts Mount Bracket – Mingxing, The product will supply to all over the world, such as: Slovakia, San Diego, Salt Lake City, Good quality, Good service is always our tenet and credo. We take every effort to control the quality, package, labels etc and our QC will check every detail during producing and before shipment. We have been willing to establish long business relationship with all those who seek the high quality products and good service. We've got set up a wide sales network across European countries, North of America, South of America, Middle East, Africa, East Asia countries.Please contact us now, you will find our expert experience and high quality grades will contribute to your business.

The factory has advanced equipment, experienced staffs and good management level, so product quality had assurance, this cooperation is very relaxed and happy!

-

Factory wholesale Micro Precision Metal Stampin...

-

2022 Good Quality Advantage Of Anodized Aluminu...

-

Factory directly Zinc Plating Color Chart - Ba...

-

Discount Price Heatsink Fan - Custom Stamping ...

-

High Performance Metal Stamping For Automotive ...

-

Factory wholesale Stamping Press - Sheet Metal...