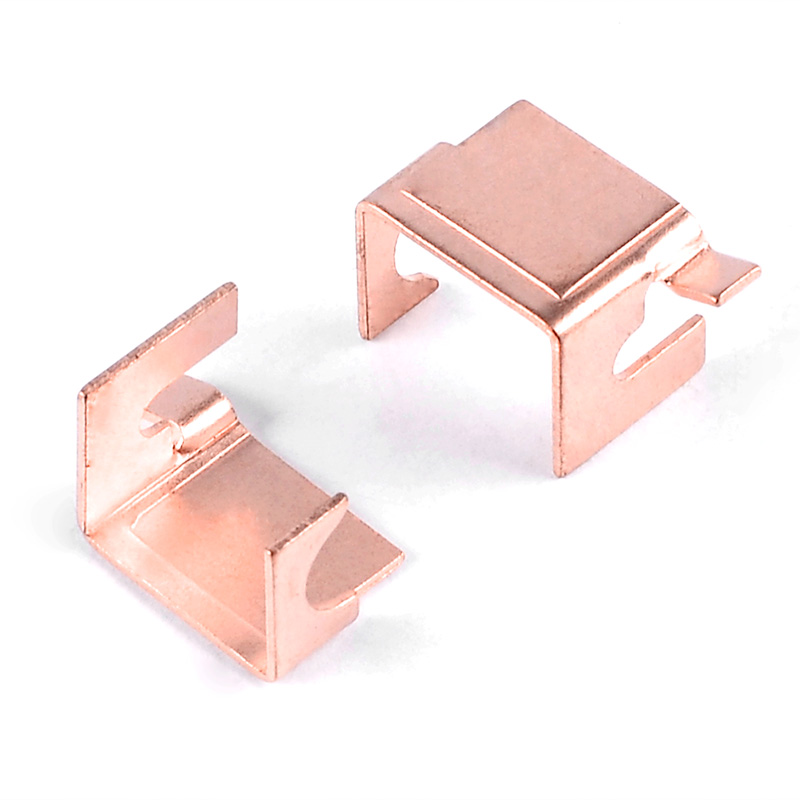

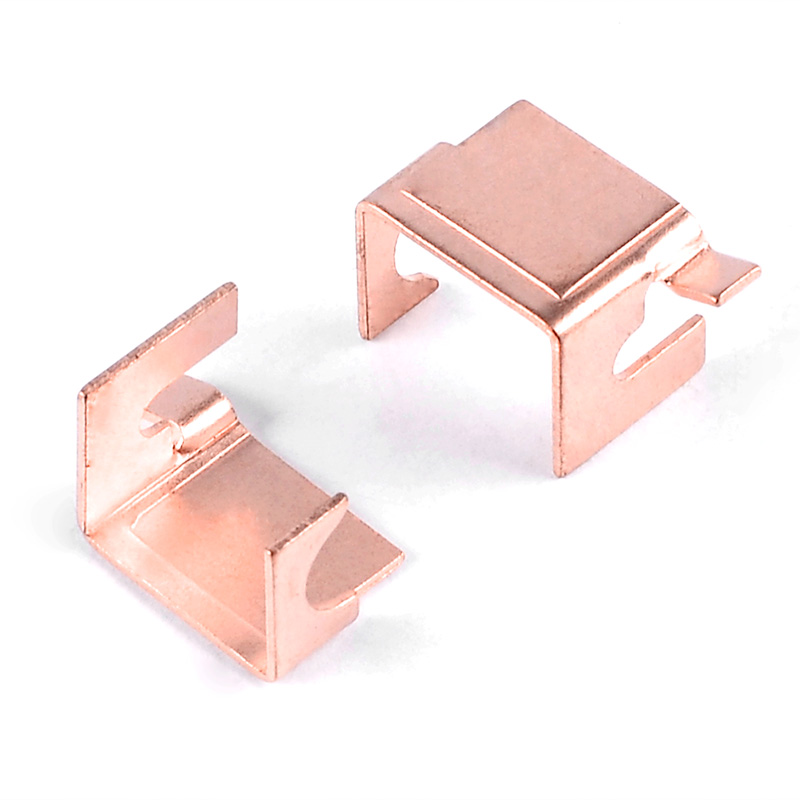

Quality Inspection for Tin Electroless Plating - Metal fabrication bending parts service custom metal stamping – Mingxing Detail:

Products Description

| Material | Stainelss steel 304 , 316 , 202 , 201 ,430 . Aluminum 6061 , 6062 ,5052 , Brass , Copper , Cold Rolled Steel , Hot Rolled Steel |

| Size Range | Min 3.0 X 3.0 mm , Max 1000 X 2000 mm |

|

Dimensions |

As client’s requirement |

| Thickness | 0.4–20.0 mm |

| Surface Treatment | Powder coating ,Painting ,Shot blasting, Polsihing ,Electrical galvanizing, Chemical galvanizing, Chrome plating , Nickel Plating, Tumbling, Passivation etc. |

| Machining | Stamping machine for 6.3 Tons to 160 Tons . |

| Support Software | Pro-E , UGS , SolidWorks ,AutoCAD |

| Quality Control | Chemical analysis, mechanical properties, impact testing, pressure testing, 3-D co-ordinate CMC, metallography, magnetic particle flaw inspection, etc. |

| MOQ | 1000pcs |

| Package | Carton and Pallet , exact part with package every pc |

Quality Control

1) Checking the raw material after they reach our factory——- Incoming quality control ( IQC)

2) Checking the details before the production line operated

3) Have full inspection and routing inspection during mass production—In process quality control(IPQC)

4) Checking the goods after they are finished—- Final quality control(FQC)

5) Checking the goods after they are finished—–Outgoing quality control(OQC)

FAQ

FREQUENTLY ASKED QUESTIONS

Q1: Are you a direct manufacturer?

A:Yes,we are direct manufacturer.We have been in this domain since 2005. And if you want, we could chatting with you on video via Wechat/Whatsapp/Messenger and any way you like to show you our plant.

Q2: How can you guarantee quality?

A: Always a pre-production sample before mass production;

Always 100% inspection before shipment;

Q3: What kind of service/products you provide?

A: Service of OEM/ one-stopservice/ assembly; From mold design, mold making, machining, fabrication, welding, surface, treatment, assembly, packing to shipping.

Product detail pictures:

Related Product Guide:

We always get the job done being a tangible workforce making sure that we can easily give you the very best quality as well as finest selling price for Quality Inspection for Tin Electroless Plating - Metal fabrication bending parts service custom metal stamping – Mingxing, The product will supply to all over the world, such as: UK, Leicester, Macedonia, Our production have been exported to more than 30 countries and regions as first hand source with lowest price. We sincerely welcome customers from both at home and abroad to come to negotiate business with us.

The goods are very perfect and the company sales manager is warmful, we will come to this company to purchase next time.

-

High Performance Acid Tin Plating Troubleshooti...

-

Discount Price Heatsink Fan - OEM Stainless St...

-

OEM/ODM China Connector Experts - Customized P...

-

Free sample for Zinc Nickel Plating - Customiz...

-

Factory Cheap Hot Station Progressive Stamping ...

-

Cheap PriceList for Precision Metal Stampings -...