|

Item name |

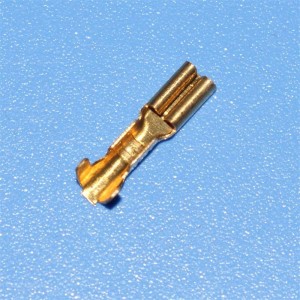

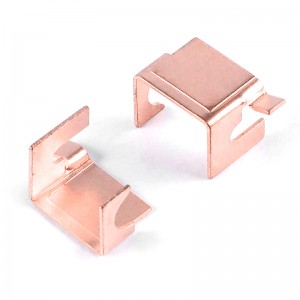

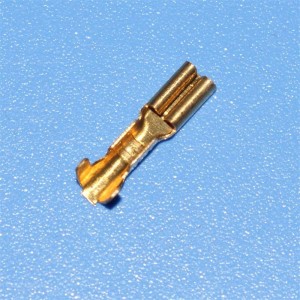

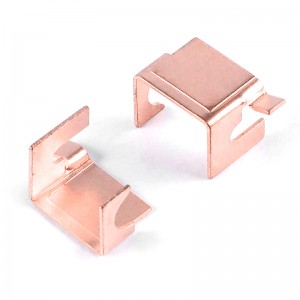

OEM Service Precision Stamping Copper Connector Terminal |

|

Material |

Beryllium Copper, Copper, Carbon Steel, Brass, Stainless steel, etc. |

|

Design |

We use the most advanced die design software Auto CAD, UG |

|

Surface Treatment |

Cleaning, Anodizing, Plating, Galvanize, Tempered, heat treatment... |

|

Tolerance |

as per customers' requirement |

|

MOQ |

Flexible, according to customer's requirement |

|

Process |

Stamping, machining, bending, deep drawing, welding, riveting |

|

Industry of Use |

Automobile, Manufacturing Machinery, Electronics, Industrial Equipment, Electrical, Construction&Decoration, Lighting, Transportation, Medical, |

Custom Stamping Terminal Capabilities

As an ISO 9001 and IATF 16949 registered professional sheet metal stamping supplier, we are dedicated to achieving superior quality through teamwork and continuous improvement of ideas and designs from customers. Any sheet metal stamping is welcomed. We will offer products and services that meet or exceed customer's expectations.

At Mingxing, we can provide full range of services for your custom electronic stamped terminals, which includes:

1. Provide OEM/ODM service.

2. Provide professional metal mould design and manufacturing services.

3. Provide metal parts moulding/ painting services.

4. Provide metal parts assembly service.

Q1: What delivery can I choose?

A: FOB/CIF/EXW/Express delivery are all avaliable.

Q2: How can I get samples?

A: We could offer 10pcs free samples for you to check quality.

Q3: What is the MOQ?

A: Usually we don't set MOQ, but the more, the cheaper. Besides, we are happy to make prototype or sample for clients to ensure quality standa

Q4. What about the lead time?

A: Average for 12 working days, open mould for 7 days and mass production for 10 days

-

Automotive Connector Cable Wire Terminal Brass ...

-

Custom Metal Stamping Connection Terminal Spare...

-

OEM Stainless Steel Contact Terminal Stamping P...

-

OEM Metal Stamping Brass Terminal Pin Connector...

-

China OEM Stamped Parts Copper Brass Electrical...

-

OEM Stamped Parts Copper Switch Contact Connect...