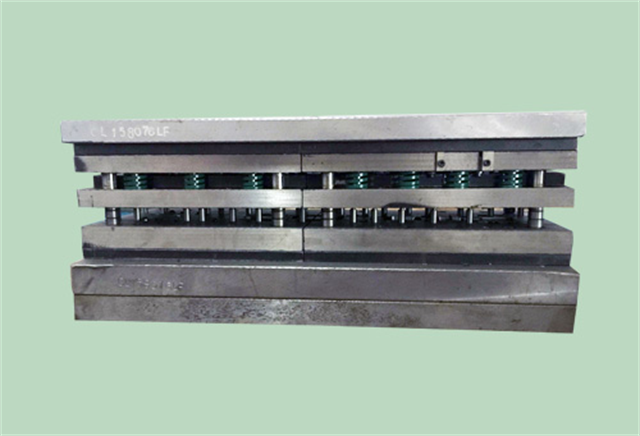

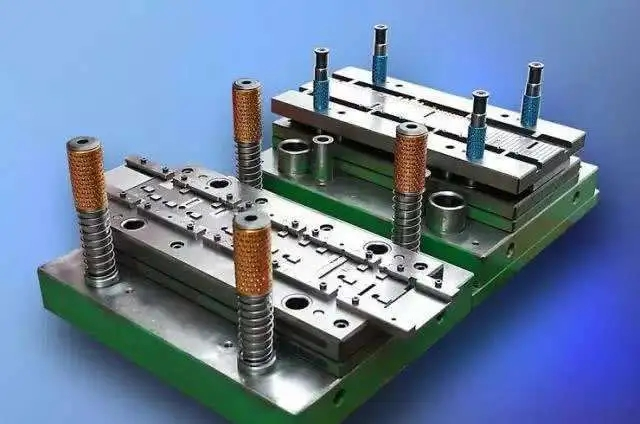

Hardware stamping die, a special process equipment for processing materials (metal or non-metal) into parts (or semi-finished products) in cold stamping process, is called cold stamping die (commonly known as cold punching die). Stamping, is a pressure processing method that uses a die mounted on a press to apply pressure to a material at room temperature to produce separation or plastic deformation to obtain the desired part.

There are many forms of hardware stamping dies, and the dies are classified according to the nature of work, die construction and die material. Join us to know what are the types of metal stamping dies.

Classification according to the nature of the process

1. Punching die. A die that separates materials along a closed or open contour line. Such as blanking die, punching die, cutting die, notching die, cutting edge die, triming die, pierce die, etc.

2. Bending die. The die that makes the sheet blank or other blank along the straight line (bending line) to produce bending deformation, so as to obtain a certain angle and shape of the workpiece.

3. Deep drawing die. It is a die to make the sheet blank into open hollow parts, or make the hollow parts further change the shape and size.

4. Forming die. It is a die that reproduces the shape of the convex and concave die directly to the blank or semi-finished workpiece, and the material itself only produces local plastic deformation. Such as expansion die, indentation die, flaring die, undulation forming die, flanging die, shaping die, etc.

5. Riveting die of metal stamping die is to use external force to make the participating parts connect or lap together in a certain order and way, and then form a whole.

Classification according to the combination of stamping processes

1) Simple operation die: (Single operation die) has only one processing station on the die, and only one type of stamping process is completed in one stroke of the press.

2) Compound die: The die has only one processing station and completes more than two types of processing in one stroke of the press.

3) Progressive die: The die has multiple stations, each station completes different processing, and each station is related in order to complete a series of different stamping processes in one stroke of the press.

Post time: Nov-26-2022