1. Touch test

Wipe the surface of the outer covering with clean gauze. The inspector needs to wear touch gloves and touch along the longitudinal direction of the stamping parts close to the surface of the stamping parts. This inspection method depends on the experience of the inspector. If necessary, the suspected area detected can be polished with an oilstone and verified, but this method is an effective and fast inspection method.

2. Oiling inspection

Wipe the surface of the outer covering with clean gauze. Then use a clean brush to evenly apply oil to the entire outer surface of the stamping along the same direction. Put the oiled stamping parts under strong light for inspection, and it is recommended to erect the stamping parts on the vehicle body. With this method, it is easy to find tiny pits, pits and ripples on the stamping parts.

3. Grinding of Flexible Yarn Mesh

Wipe the surface of the outer covering with clean gauze. Use flexible sand mesh to grind the surface of stamping parts to the whole surface along the longitudinal direction, and any pitting and indentation will be easily found.

4. Oil stone grinding

1) First, clean the surface of the outer cover with clean gauze, and then polish with an oilstone (20 × twenty × 100mm or more), and relatively small oilstone shall be used to polish the places with arc and hard to reach (for example: 8 × 100mm semi-circular stone)

2) The selection of the particle size of oilstone depends on the surface condition (such as roughness, galvanization, etc.). Fine grained oilstone is recommended. The grinding direction of the oilstone is basically along the longitudinal direction, and it fits the surface of the stamping parts well. In some special places, the horizontal grinding can also be supplemented.

5. Visual inspection

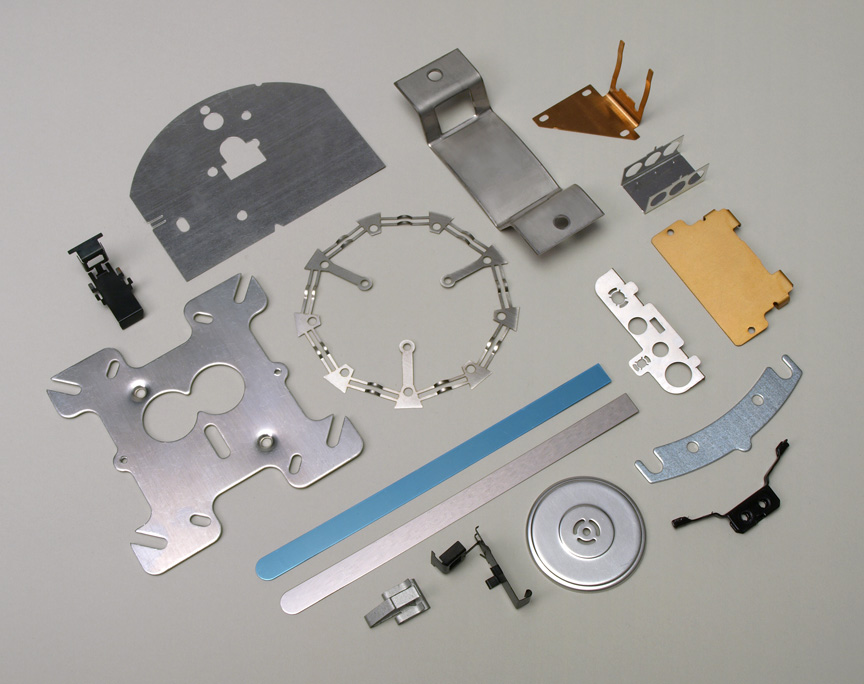

Visual inspection is mainly used to find the appearance abnormalities and macro defects of stamping parts

6. Inspection with inspection tools

Put the stamping parts into the inspection tool, and inspect the stamping parts of Nanpi according to the operation requirements of the inspection tool manual.

Post time: Sep-25-2023