Because most of the domestic mold manufacturing enterprises are small and medium-sized enterprises, and quite a few of these enterprises are still in the traditional workshop production management stage, often ignoring the stability of the mold, resulting in long mold development cycle, high manufacturing costs, and seriously restricting the pace of enterprise development.

What is continuous stability? Continuous stability is divided into continuous process stability and continuous production stability. Continuous process stability refers to the process plan that meets the requirements of stable production of qualified products; The continuous stability of production refers to the production capacity with continuous stability in the production process.

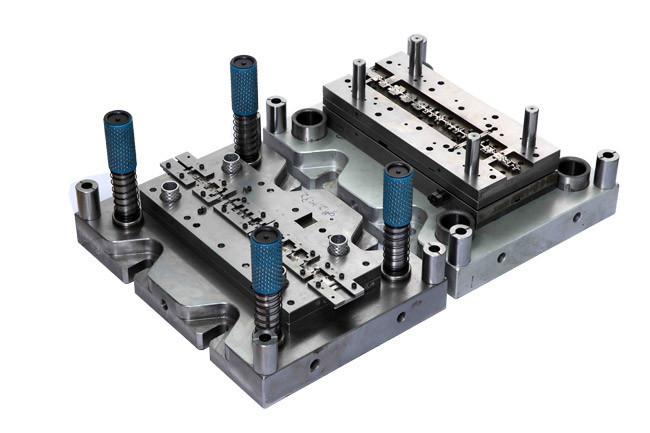

First, let's take a look at the main factors that affect the continuous stability of metal stamping parts, respectively: the use of mold materials; Strength requirements for die structure; Stability of stamping material properties; Fluctuation characteristics of material thickness; Change range of materials; Resistance of stretching tendon; Variation range of blank holder force; Selection of lubricants.

As we all know, the metal materials used in stamping dies involve many kinds. Due to the different functions of various parts in the dies, the requirements and selection principles for their materials are also different. Therefore, how to reasonably select mold materials has become one of the most important tasks in mold design.

When selecting die materials, in addition to the requirements that the materials must have high strength, high wear resistance and appropriate toughness, the characteristics and output requirements of the processed product materials must be fully considered, so as to meet the stability requirements of die forming.

In actual operation, because die designers tend to choose die materials based on their personal experience, the problem of unstable die forming due to improper selection of die parts' materials often occurs in metal stamping.

It is worth noting that in the process of metal stamping, each type of stamping plate has its own chemical composition, mechanical properties and characteristic values closely related to the stamping performance. The instability of the performance of stamping materials, the fluctuation of the thickness of stamping materials, and the change of stamping materials not only directly affect the precision and quality of metal stamping processing, but also may cause damage to the mold.

In order to solve the problem of die stability of metal stamping parts, the following aspects should be strictly checked:

1. In the process formulation stage, through the analysis of products, the possible defects of products in manufacturing can be predicted, so as to develop a stable manufacturing process plan;

2. Implement the standardization of production process and production process;

3. Establish a database and constantly summarize and optimize it; With the aid of CAE analysis software system, the optimal solution is obtained.

Post time: Oct-22-2022