The dimensional accuracy of blanking parts refers to the difference between the actual size of blanking parts and the basic size on the drawing. The smaller the difference, the higher the accuracy. This difference includes two deviations: one is the deviation of the blanking part from the punch or die size, and the other is the manufacturing deviation of the die itself.

Impact of blanking clearance on blanking force, unloading force, pushing force and jacking force

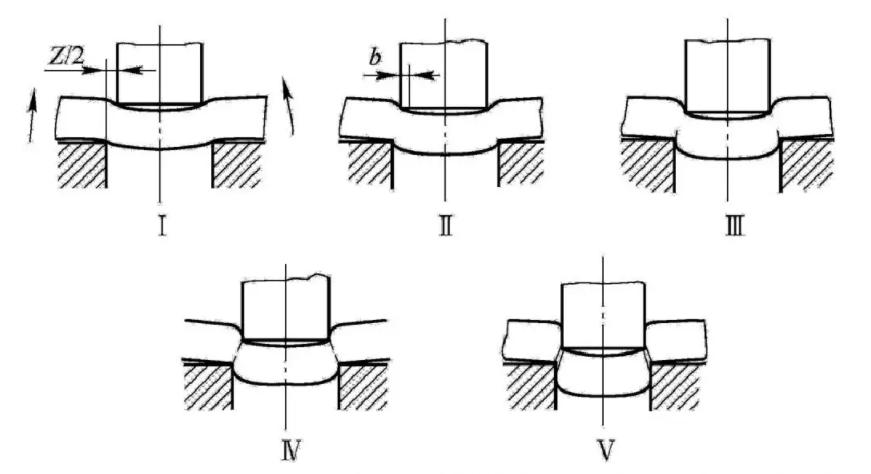

With the increase of clearance, the tensile stress of the material during blanking will increase, the material is easy to break and separate, and the blanking force will be reduced to a certain extent. However, under normal circumstances, clearance does not greatly affect the cutting force.

The clearance has a significant effect on the unloading force and pushing force. The unloading force and pushing force will decrease with the increase of clearance. Generally, when the one-sided clearance increases to 15%~25% of the material thickness, the unloading force almost drops to zero. However, when the gap continues to increase, the burr will increase, and the unloading force and ejector force will increase rapidly.

Influence of Blanking Clearance on Die Life

The failure forms of stamping dies generally include wear, chipping, deformation, expansion and fracture.

The blanking force is mainly concentrated on the cutting edge of punch and die. The edge deformation and end face wear are intensified, even the edge breaks.

Therefore, in order to reduce the wear of male and female dies and prolong the service life of dies, it is necessary to appropriately adopt a larger clearance value on the premise of ensuring the quality of blanking parts. If small clearance is adopted, it is necessary to improve the hardness and wear resistance of the die, improve the manufacturing accuracy of the die, and use good lubrication during blanking to reduce wear.

Determination of reasonable clearance value

Therefore, in the actual production of stamping, a range value is specified for the clearance mainly based on the comprehensive consideration of the three factors of the section quality, dimensional accuracy and die life of blanking parts. This clearance range is called reasonable clearance. The minimum value of this range is called minimum reasonable clearance (Zmin), and the maximum value is called maximum reasonable clearance (Zmax). Considering that the wear in the production process makes the clearance larger, the minimum reasonable clearance (Zmin) should be adopted when designing and manufacturing new molds.

Post time: Nov-04-2022