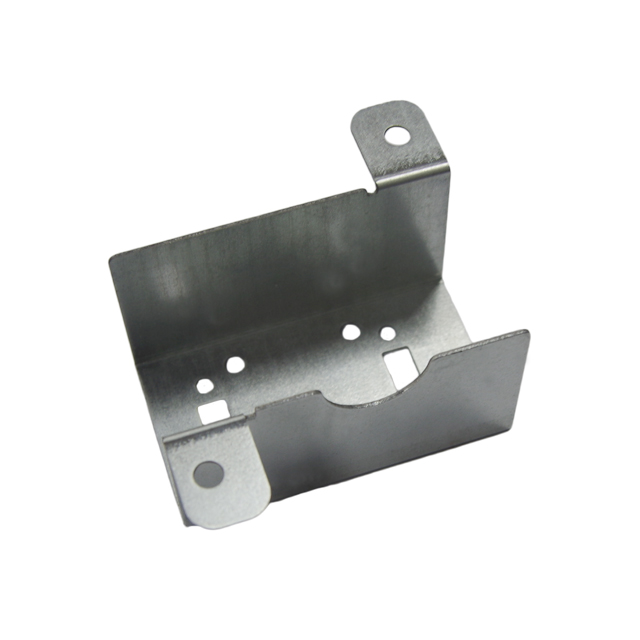

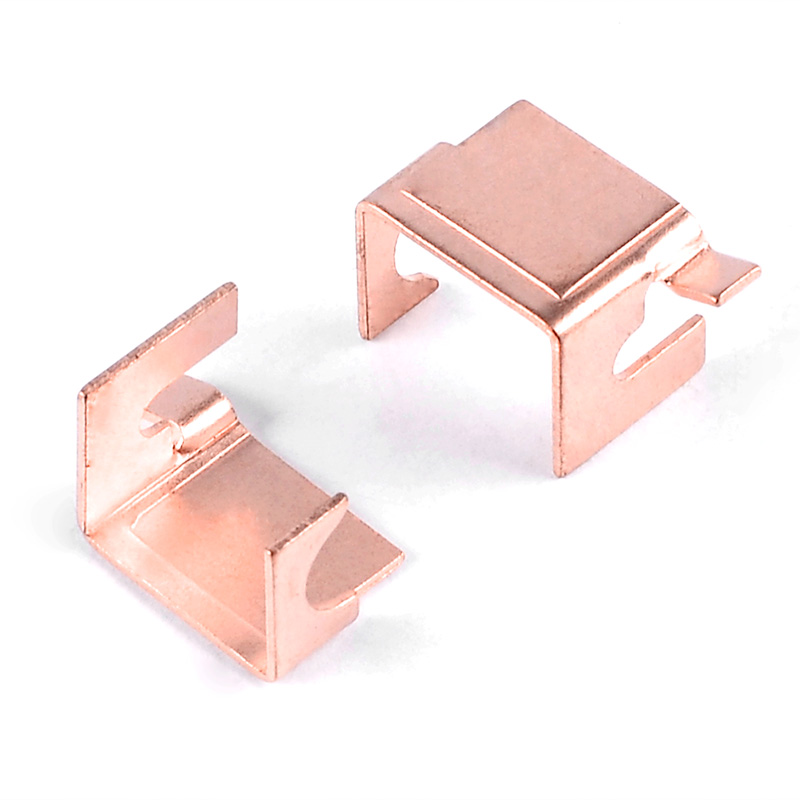

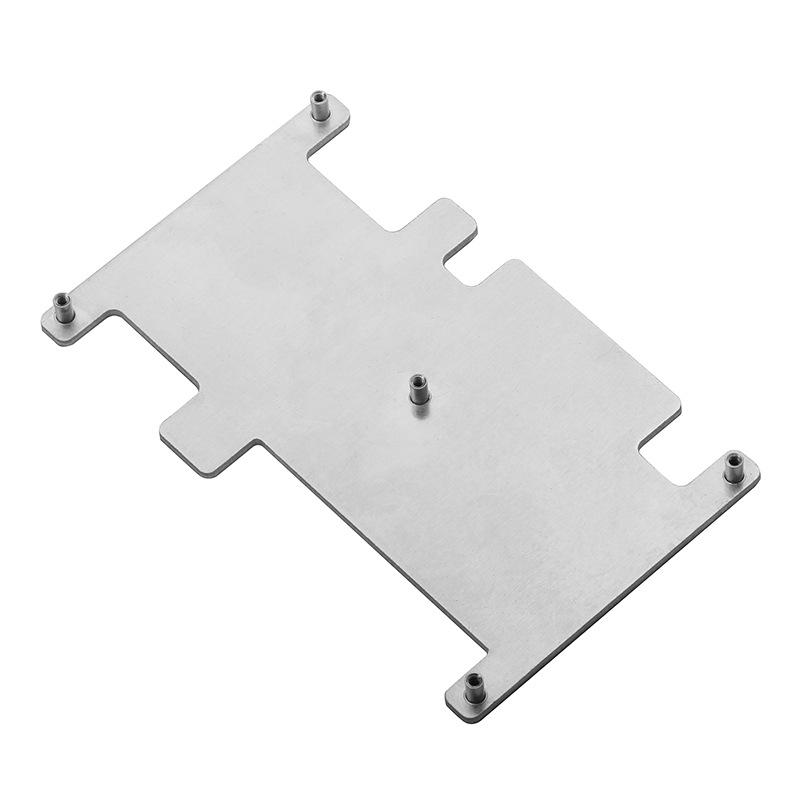

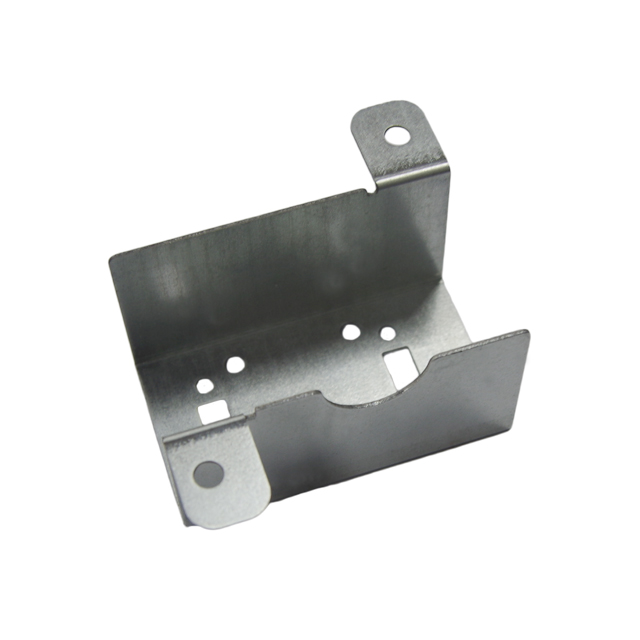

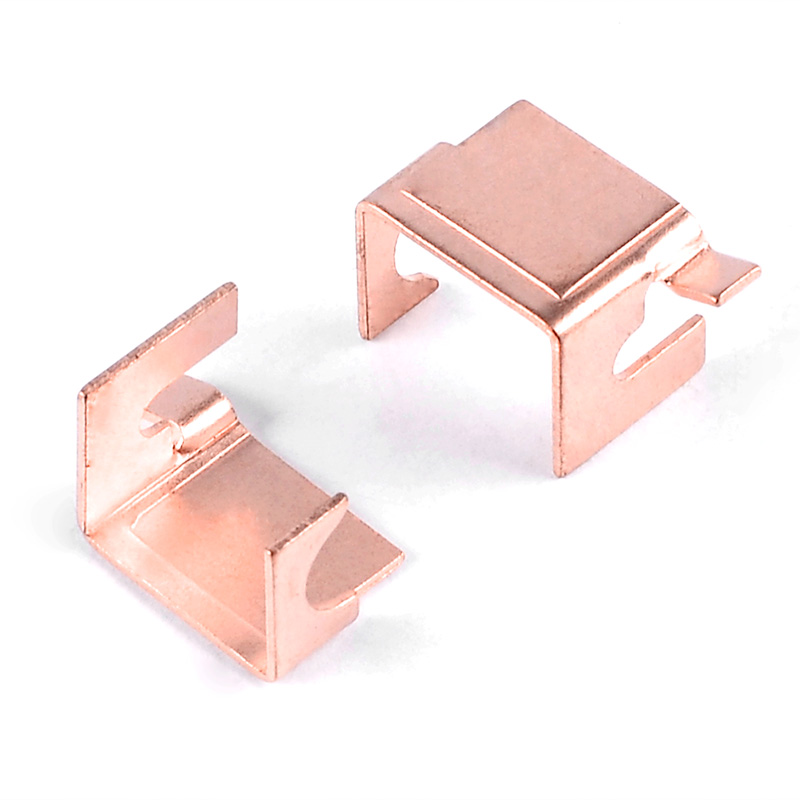

Hot sale Factory Copper Busbar Ampacity - Aluminum heat sink for BMS 48V 65A 13s Lithium Battery Protection Circuit Board for EV Application – Mingxing Detail:

Product Description

We have a wide repertoire of capabilities, and OEMs ranging from appliances to sporting goods have put their trust in our sturdy and reliable components. Our tight tolerances ensure that what you receive matches the dimensions we’re given every time. Our automated process also ensures that each part is manufactured in exactly the same, repeatable conditions. This allows us to better monitor the progression of every component, from start to finish. These automated machines supplement our very reliable and skilled machinists. This combination of top-notch stamping machines, quality control machines, and our team of adept craftsmen yields a high level in manufacturing quality.

Our custom metal stamping services include many capabilities, such as:

● Progressive Die Stamping

● Shallow Draw Stamping

● Blanking

● Piercing

● Bending

● Coining

● Forming

● Secondary Production

FAQ

FREQUENTLY ASKED QUESTIONS

Q. Are you a factory or a trade company?

A:We’re a factory with over 20 years experience in the heat sink field.It is a enterprise that professionally design and produce Heat sinks, electronic components, auto parts and other stamping products.

Q. How to get a quotation?

A: Please send us info such as drawing,material surface finish,quantity.

Q. What about the lead time?

A: Average for 12 working days, open mould for 7 days and mass production for 10 days

Q. Do the products of all the colors are the same with same surface treatment?

A: No. about powder coating, the bright-color will higher than white or gray. About the Anodizing, colorful will higher than silver, and black higher than colorful.

Product detail pictures:

Related Product Guide:

Our business sticks for the basic principle of Quality could be the life with the firm, and track record will be the soul of it for Hot sale Factory Copper Busbar Ampacity - Aluminum heat sink for BMS 48V 65A 13s Lithium Battery Protection Circuit Board for EV Application – Mingxing, The product will supply to all over the world, such as: Montreal, Florida, Spain, Hard work to keep making progress, innovation in the industry, make every effort to first-class enterprise. We try our best to build the scientific management model, to learn abundant professional knowledge, to develop advanced production equipment and production process , to create the first-call quality products, reasonable price , high quality of service , quick delivery , to give you create new value .

We have been appreciated the Chinese manufacturing, this time also did not let us disappoint,good job!

-

China Manufacturer for Metal Stamping For Autom...

-

Factory Supply Easy Nickel Plating - Customize...

-

PriceList for Precision Sheet Metal Stamping Pa...

-

High Performance Acid Tin Plating Troubleshooti...

-

One of Hottest for Nickel Electro Plating - Cu...

-

Discount Price Heatsink Fan - OEM Stainless St...