Vim feem ntau ntawm domestickev tsim pwmcov tuam txhab lag luam yog cov lag luam me thiab nruab nrab, thiab qee qhov ntawm cov lag luam no tseem nyob rau hauv cov tsoos rhiav kev tswj cov txheej txheem ntau lawm, feem ntau tsis quav ntsej qhov kev ruaj ntseg ntawm pwm, ua rau lub pwm ntev pwm kev loj hlob, cov nqi tsim khoom siab, thiab kev txwv nruj heev. ntawm kev txhim kho kev lag luam.

Kev ruaj ntseg txuas ntxiv yog dab tsi?Nruam stability yog muab faib ua cov txheej txheem nruam stability thiab nruam ntau lawm stability.Kev ruaj ntseg ntawm cov txheej txheem txuas ntxiv yog hais txog cov txheej txheem txheej txheem uas ua tau raws li cov kev xav tau ntawm kev ruaj khov ntawm cov khoom tsim nyog;Kev ruaj khov ntawm kev tsim khoom tsis tu ncua yog hais txog lub peev xwm ntau lawm nrog kev ruaj khov nyob rau hauv cov txheej txheem ntau lawm.

Ua ntej, cia peb saib cov ntsiab lus tseem ceeb uas cuam tshuam rau kev ruaj ntseg txuas ntxiv ntawmhlau stamping qhov chaw, ntsig txog: kev siv cov khoom pwm;Lub zog xav tau rau cov qauv tuag;Stability ntawm cov khoom siv stamping;Hloov cov yam ntxwv ntawm cov khoom thickness;Hloov cov khoom siv;Tsis kam ntawm stretching leeg;Variation ntau yam ntawm qhov tsis muaj zog tuav;Kev xaiv cov roj nplua nyeem.

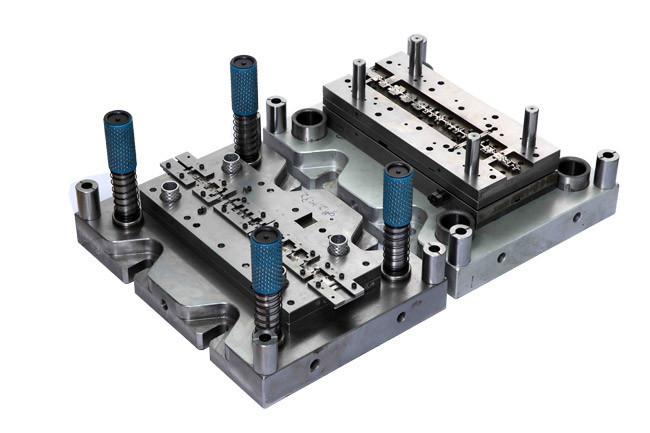

Raws li peb txhua tus paub,cov ntaub ntawv hlausiv nyob rau hauv stamping tuag koom nrog ntau yam.Vim muaj cov haujlwm sib txawv ntawm ntau qhov chaw hauv cov tuag, cov kev cai thiab kev xaiv cov qauv rau lawv cov ntaub ntawv kuj txawv.Yog li ntawd, yuav ua li cas thiaj li xaiv cov khoom pwm tsim nyog tau dhau los ua ib txoj haujlwm tseem ceeb tshaj plaws hauv kev tsim pwm.

Thaum xaiv cov khoom siv tuag, ntxiv rau cov kev cai uas cov ntaub ntawv yuav tsum muaj lub zog siab, siab hnav tsis kam thiab tsim nyog toughness, cov yam ntxwv thiab cov khoom tsim tawm ntawm cov khoom siv ua tiav yuav tsum tau txiav txim siab tag nrho, thiaj li ua tau raws li qhov yuav tsum tau muaj kev ruaj ntseg ntawm kev tuag. .

Hauv kev ua haujlwm tiag tiag, vim tias cov neeg tsim khoom tuag yuav xaiv cov khoom siv tuag raws li lawv tus kheej kev paub, qhov teeb meem ntawm kev tuag tsis ruaj khov vim kev xaiv tsis raug ntawm cov khoom siv tuag feem ntau tshwm sim hauv cov hlau stamping.

Nws yog tsim nyog sau cia tias nyob rau hauv tus txheej txheem ntawmhlau stamping, txhua homstamping phajNws muaj nws tus kheej cov tshuaj muaj pes tsawg leeg, txhua yam khoom thiab cov yam ntxwv muaj txiaj ntsig zoo cuam tshuam nrog kev ua haujlwm stamping.Qhov tsis ruaj khov ntawm kev ua tau zoo ntawm cov khoom siv stamping, qhov hloov pauv ntawm cov thickness ntawm cov ntaub ntawv stamping, thiab kev hloov ntawm cov ntaub ntawv stamping tsis tsuas yog cuam tshuam ncaj qha rau cov precision thiab zoo.hlau stamping txheej txheem, tab sis kuj tuaj yeem ua rau puas rau pwm.

Yuav kom daws tau qhov teeb meem ntawm kev tuag stability ntawm cov hlau stamping qhov chaw, cov nram qab no yuav tsum tau nruj me ntsis xyuas:

1. Nyob rau hauv cov txheej txheem formulation theem, los ntawm kev soj ntsuam ntawm cov khoom, qhov ua tau tsis xws luag ntawm cov khoom nyob rau hauv manufacturing yuav kwv yees, thiaj li mus tsim ib tug ruaj khov txheej txheem kev npaj;

2. Ua raws li cov txheej txheem tsim khoom thiab cov txheej txheem tsim khoom;

3. Tsim kom muaj ib qho chaw khaws ntaub ntawv thiab niaj hnub sau thiab ua kom zoo dua;Nrog kev pab ntawm CAE tsom xam software system, qhov kev daws teeb meem zoo tshaj plaws tau txais.

Post lub sij hawm: Oct-22-2022