Kho vajtsestampingtuagsiv ntau yam hlau thiab cov ntaub ntawv tsis yog hlau, uas feem ntau yog carbon steel, alloy steel, cam khwb cia hlau, cam khwb cia hlau, nyuaj alloy, tsawg melting point alloy, zinc-raws li alloy, aluminium bronze, thiab lwm yam.

Cov khoom siv rau kev tsim cov khoom siv hlau stamping tuag yuav tsum muaj siab hardness, siab zog, siab hnav tsis kam, tsim nyog toughness, siab hardenability thiab tshav kub kho yam tsis muaj deformation (los yog tsawg deformation) thiab quenching tsis yooj yim rau tawg thiab lwm yam khoom.

Tsim nyog xaiv cov khoom siv kho vajtse stamping tuag cov ntaub ntawv thiab kev siv cov txheej txheem kho cua sov kom raug yog tus yuam sij los xyuas kom meej lub neej ntawm kev tuag.Rau cov tuag nrog cov kev siv sib txawv, nws yuav tsum tau txiav txim siab raws li nws qhov kev ua haujlwm, kev ntxhov siab thiab kev ua haujlwm ntawm cov khoom siv, cov ntim ntau lawm thiab kev tsim khoom, thiab lwm yam, thiab tsom mus rau cov kev xav tau ntawm cov lus hais saum toj no, thiab tom qab ntawd ua qhov sib xws. xaiv cov txheej txheem steel thiab kev kho cua sov.

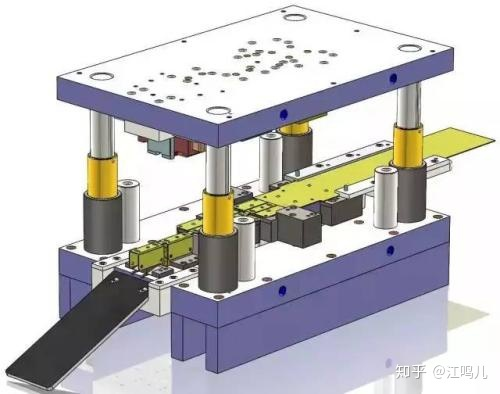

Thaum ntau lawm batch ntawm nplua nuj thiab tiavstamping qhov chawyog loj, cov ntaub ntawv ntawm kev ua hauj lwm qhov chaw ntawm lub tuag rau kho vajtse stamping qhov chaw, xws li lub convex tuag thiab concave tuag, yuav tsum tau xaiv los ntawm cov hlau tuag uas zoo thiab hnav tsis kam.Rau cov ntaub ntawv ntawm qhov chaw ntawm lwm cov txheej txheem cov txheej txheem thiab cov txheej txheem auxiliary qhov chaw ntawm cov tuag, lawv kuj yuav tsum tau txhim kho raws li.Thaum cov batch tsis loj, qhov yuav tsum tau ua ntawm cov khoom siv yuav tsum tau so kom tsim nyog los txo tus nqi.

Thaum cov khoom yuav tsum tau nias thiab ua tiav yog ib qho nyuaj los yog deformation kuj loj, lub convex thiab concave tuag ntawm lubxuas nrig ntaus tuagyuav tsum tau ua los ntawm cov ntaub ntawv nrog zoo hnav tsis kam thiab siab zog.Thaum kos cov hlau tsis sib sib zog nqus, aluminium bronze concave tuag tuaj yeem siv vim nws muaj cov khoom zoo dua los tiv thaiv cov nplaum.Cov lus qhia pillar qhia hav txwv yeem yuav tsum hnav tsis kam thiab zoo toughness, yog li ntau cov pa roj carbon steel nto carburization quenching.

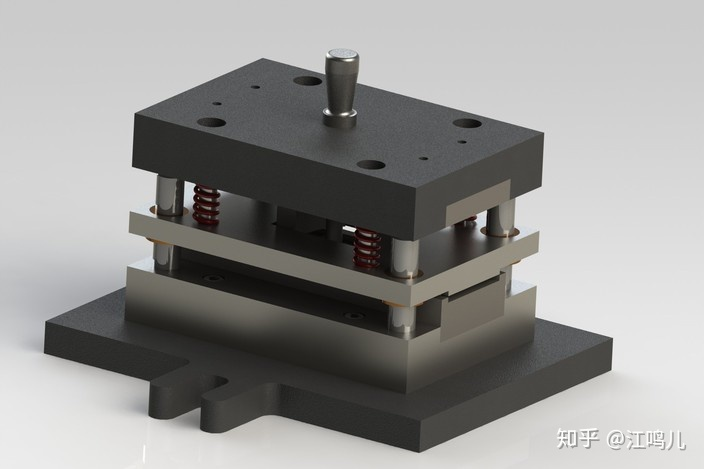

Rau cov phaj ruaj khov thiab tso tawm hom phaj, tsis tsuas yog lawv yuav tsum muaj lub zog txaus, tab sis kuj yuav tsum tau deformation me ntsis thaum lub sijhawm ua haujlwm.Tsis tas li ntawd, koj tuaj yeem siv kev kho mob khaub thuas thiab kev kho mob sib sib zog nqus, kev kho lub tshuab nqus tsev thiab cov txheej txheem ntxiv dag zog los txhim kho kev ua haujlwm ntawm pwm qhov chaw.Rau convex, concave tuag ua hauj lwm tej yam kev mob tsis zoo txias extrusion tuag, yuav tsum tau xaiv nrog txaus hardness, lub zog, toughness, hnav tsis kam thiab lwm yam txhua yam khoom ntawm zoo tuag steel, thaum yuav tsum muaj ib tug tej yam liab hardness thiab thermal qaug zog, thiab lwm yam.

Post lub sij hawm: Jan-10-2023