Ana ci gaba da samun ci gaba a cikin sabbin fasahar baturi mai ƙarfi, wanda ke haifar da canza buƙatun kayan aikin baturi.A halin yanzu, yawancin masana'antun batir lithium suna walda filayen tagulla akan filayen aluminium waɗanda ke haɗa wayoyin baturi.A cikin hanyoyin sarrafa al'ada, ingantaccen walda tsakanin tagulla da igiyoyin aluminium yana samun cikas ta iyakancewar abu, ko dai yana haifar da rashin nasarar walda, rashin isasshen ƙarfin walda, ko hana tsadar kaya.

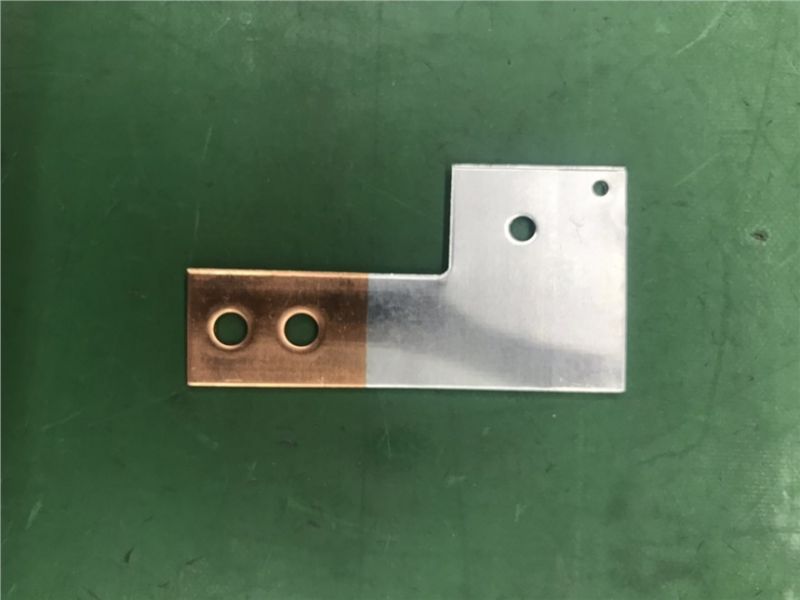

Domin saduwa da abokin ciniki da buƙatun kasuwa, ƙungiyar fasaha a Dongguan Mares sun yi amfani da kayan aikin watsa kwayoyin halitta don cimma waldi tsakanin aluminum da tube na jan karfe.Ana nuna sakamakon walda a cikin hoton da ke sama: kamannin yana da kyau, kabu ɗin weld ƙarami ne, kuma ƙarfin ja yana da girma.Sabbin abokan cinikin batirin makamashi da yawa sun karɓi kuma sun gane wannan samfurin.

Fasahar waldawar kwayoyin halitta tana nuna kyakkyawan sakamako lokacin da aka yi amfani da su ga yawancin kayan ƙarfe, musamman a cikin ƙarfe na walda tare da haɓakar zafi mai ƙarfi kamar aluminum, gami da jan ƙarfe, da tabbatar da inganci da aminci.

Welding tsakanin jan karfe da aluminum tube ya dace da farko don haɗin fuska-da-fuska.Saboda girman reactivity na aluminum, yana da wuyar samun iskar shaka yayin aikin walda.Saboda haka, daidaitaccen sarrafa zafin walda da lokaci yana da mahimmanci don hana karkatar da igiyoyin jan ƙarfe-aluminum.

Pre-welding Cleaning:

Kafin yin waldi mai yaduwa, kayan aiki tare da tabon mai akan saman jan karfe-aluminum tube ya kamata a tsaftace su tare da kaushi na halitta ko tururin sauran ƙarfi (kamar acetone).Ya kamata a tsaftace Layer oxide a cikin kewayon 10mm na yankin waldawa da kyau ta amfani da yashi na ƙarfe ko fayilolin emery, musamman ma saman ciki na haɗin gwiwa.

Tsarin walda:

Tsayawa daidaitattun jeri na tagulla-aluminum tsiri workpieces a cikin dacewar matsayi a ko'ina cikin tsarin yada kwayoyin halitta yana da mahimmanci don tabbatar da daidaito mai inganci.Ana iya samun wannan yawanci ta amfani da na'urorin daidaitawa, ko kuma tare da taimakon wasu kayan aikin taimako.Ƙididdigar zafin walda da riƙe lokacin matsa lamba dangane da kauri na walda da yankin tuntuɓar tagulla da aluminum yana da mahimmanci don hana al'amura masu inganci kamar nakasar thermal.

Lokacin aikawa: Oktoba-19-2023