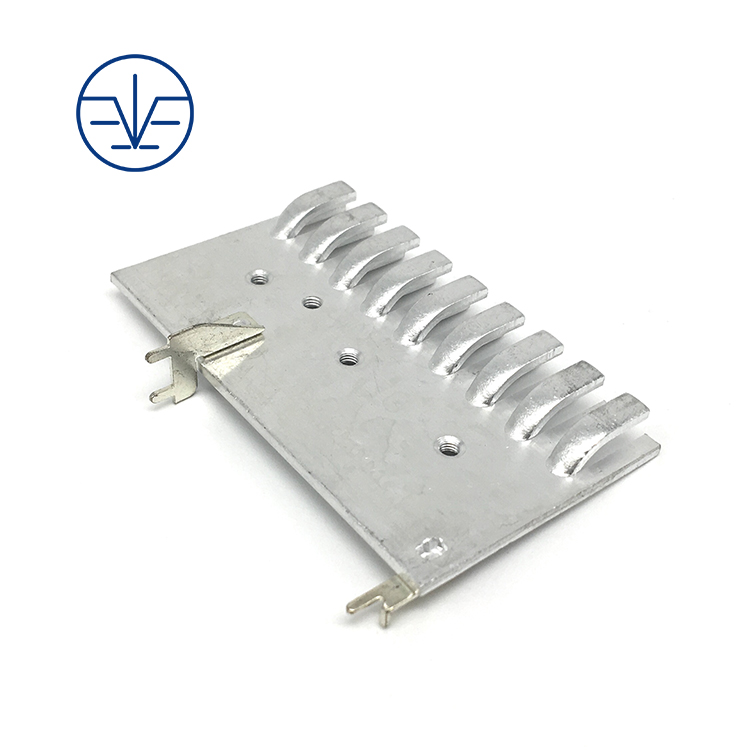

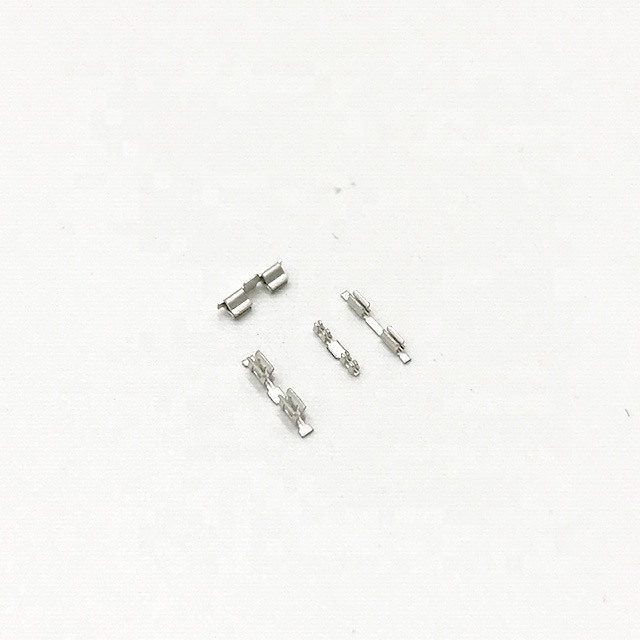

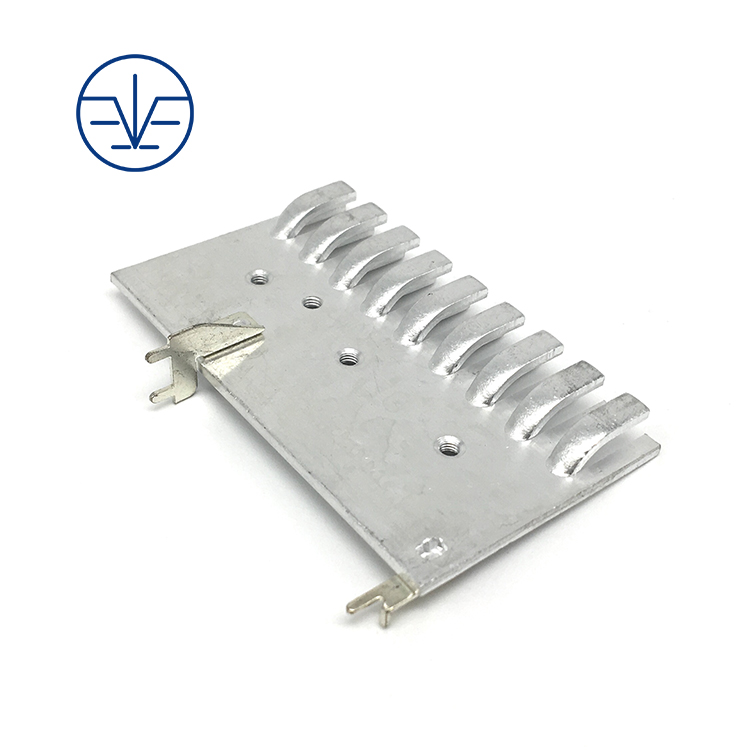

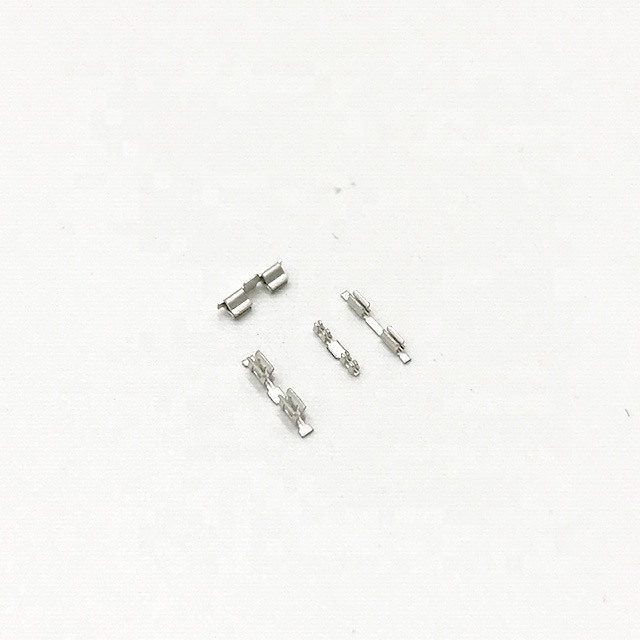

Good quality Precision Metal Stamping Malaysia - China OEM Service Copper Busbar Shunt with Screw – Mingxing Detail:

Product Description

|

Material available |

C1100, T2, Bronze, brass, copper alloy, aluminum alloy, tin plated, nickel silver |

|

Surface treatment |

zinc/nickel/chrome/tin plating(colour or natural), Galvanization, anodizing, oil spraying, powder coating, polishing, passivate, brush, wire drawing, painting, etc. |

|

Metal processing available |

Tooling making, Prototype, Cutting, Stamping, Welding, Tapping, Bending and Forming, Machining, Surface treatment, Assembly |

|

Specification |

OEM/ODM, as per client’ s drawing or sample |

|

Certificate |

ISO9001:2015/IATF 16949/SGS/RoHS |

|

Tolerance |

0.02mm-0.1mm |

|

Software |

Auto CAD, Soliworks, PDF |

|

Application |

automotive parts, railroad parts,medical parts, marine parts, lighting parts, pump body, valve parts,architectural parts and furniture parts, etc. |

Custom Busbars Capabilities

The superior ampacity of electrical bus bars help achieve better thermal control in enclosed applications. Aluminum and Copper Bus Bar also improves the reliability of a power or electrical grounding connection by eliminating the need for a mechanical cable lug crimp.

Choose Mingxing fabricated bus bar to:

- Decrease system costs

- Eliminate wiring errors

- Improve reliability and thermal characteristics

- Lower inductance and impedance

- Increase interconnection method options

- Reduce capacitance

Why choose us?

Mingxing is ITAF-certified and ISO 9001-certified, so our clients can rely on the safety and quality of our stamped products. For over 24 years, our company has designed and manufactured assemblies, custom metal stamping parts, and more. We have well-established facilities dedicated to producing high-quality products with state-of-the-art equipment and the top metal working techniques.

At Mingxing, our capabilities for custom copper busbars includes:

1. RoHS Compliance

2. Barrel and Rack Plating

3. Material Selection Suggestion

4. Progressive Die Stamping

5. Just-in-Time Delivery

6. Design and Assembly

7. Prototyping Services

FAQ

FREQUENTLY ASKED QUESTIONS

Q: How long can I receive your quotation?

A: Thank you so much for your kind support, and after receiving your drawing, specifications and details ;our engineer will review the structure and evaluate the cost within 48 hours.

Q: What’s your advantage of stamping services?

A: Firstly, Mingxing offers fully automatic fabrication services for competitive cost and efficient productivity. And most of our machines are equipped;with high precision tolerance and dimension.

Q: What will you do when the project is placed on you?

A: It depends on what kinds of project we are dealing with, the automotive one will be different from the others. But generally we will start the mold manufacture when getting your approval. And the first sample will be offered within 7-14 weekdays and then send for FAI testing, we will send you the sample and testing report when it’s qualified.

Q: What will you do for after-service?

A: When our metal parts apply to your products, we will follow-up and await for your feedback.

If need any help of the assembly or other matters, our professional engineer will give you a best solutions.

Product detail pictures:

Related Product Guide:

As for competitive selling prices, we believe that you will be searching far and wide for anything that can beat us. We will state with absolute certainty that for such excellent at such charges we are the lowest around for Good quality Precision Metal Stamping Malaysia - China OEM Service Copper Busbar Shunt with Screw – Mingxing, The product will supply to all over the world, such as: Turkey, Peru, Germany, After years' creating and developing, with the advantages of trained qualified talents and rich marketing experience, outstanding achievements were gradually made. We get good reputation from the customers due to our good solutions quality and fine after-sale service. We sincerely wish to create a more prosperous and flourishing future together with all the friends home and abroad!

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.

-

Massive Selection for Tin Nickel Plating - OEM...

-

Factory directly Chipset Heat Sink Not Detected...

-

Original Factory Zinc Plating At Home - Custom...

-

Hot Selling for Tin Plating Process - Stainles...

-

Popular Design for Heat Sink Calculator - Cust...

-

Low price for Electroless Nickel Plating - OEM...