Factory source Nickel Plating Process Flow Chart - Customized Precision Aluminum CNC Turning Parts Anodized CNC Machining Part – Mingxing Detail:

Product Description

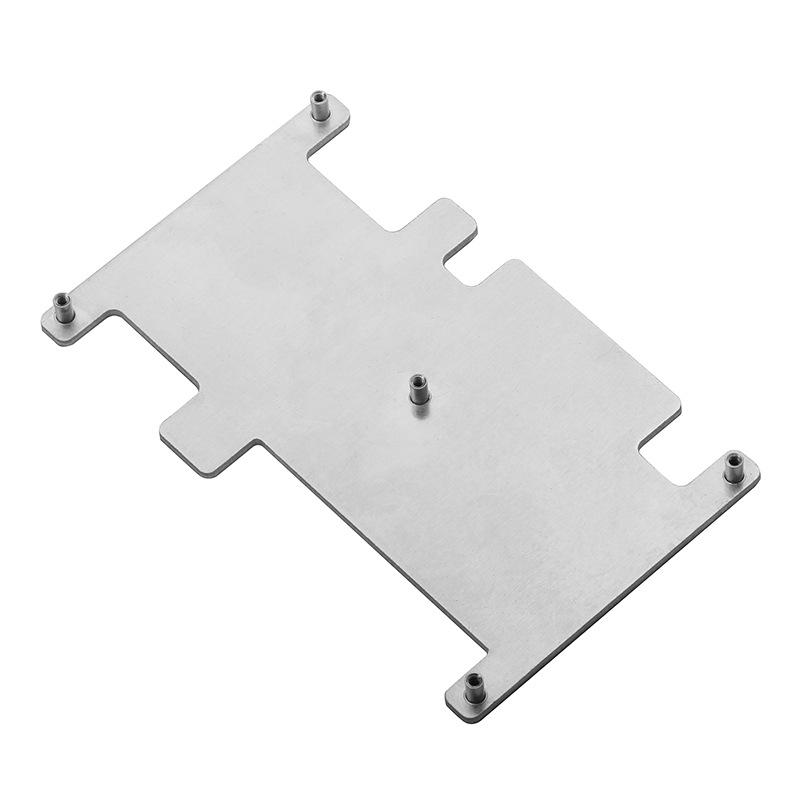

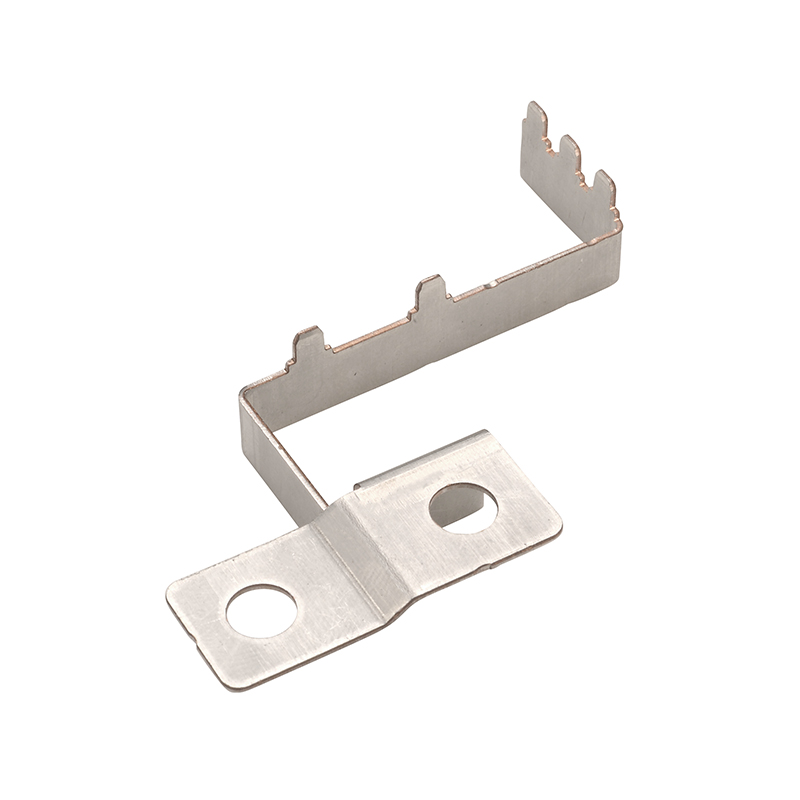

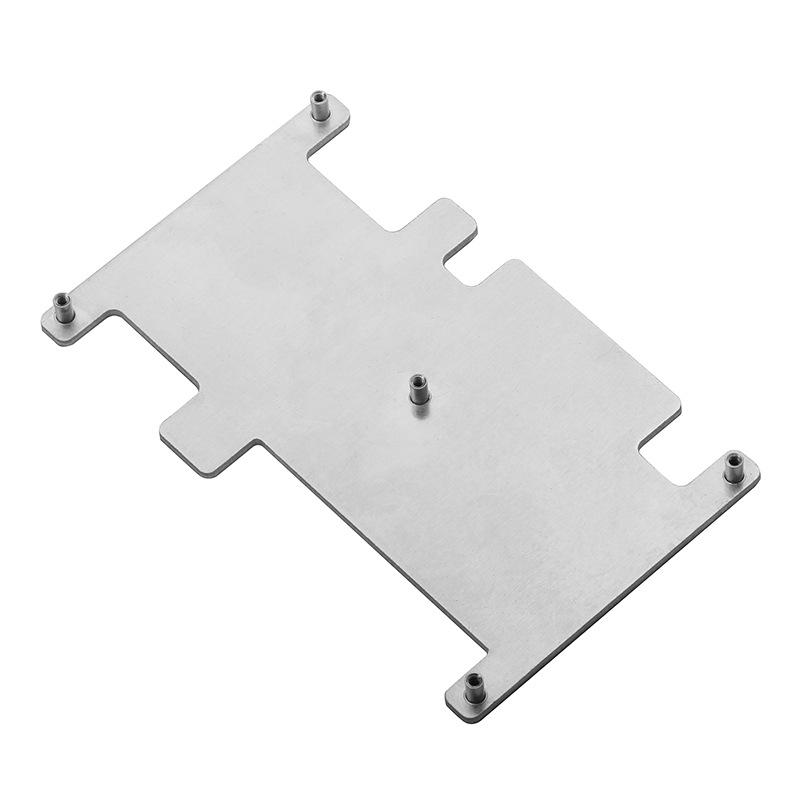

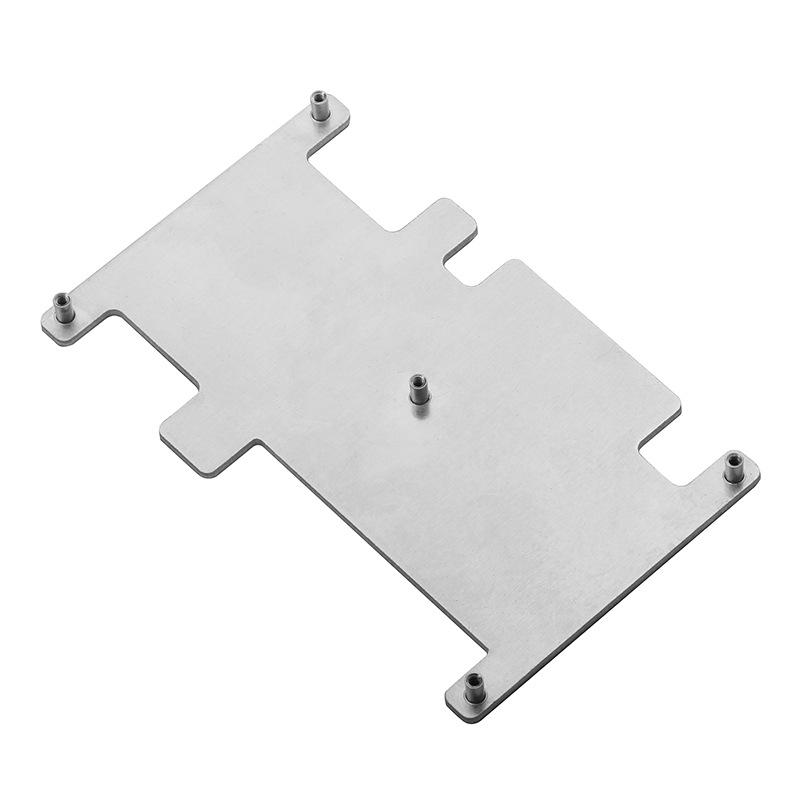

| Product name | Customized Precision Aluminum CNC Turning Parts Anodized CNC Machining Part |

| Material | Aluminum alloy, AL6063, AL6061 |

| Size | Support for customization |

| Surface finishing | Anodizing, powder coating, sandblasting, etc,.. |

| Color | Black, silver, gold (support to change) |

| Process | CNC milling and turning, drilling, grinding, bending, stamping, tapping |

| MOQ | Small quantity is acceptable |

| Quality | 100% inspection |

| Delivery time | 7-14 days |

Custom Anodized Aluminum CNC Machining Parts Capabilities

We are a professional production factory specialized in sheet metal fabrication mainly stamping, deep drawing, welding and wire bending. We have our own equipments for a whole production flow, from mould design, prototypes develop, processing, assembly to surface coating. We have a high level team of engineers to provide you with the most practical and cost-effective solutions. Our workers are experienced and our quality control is strict. We have the ability to provide clients with high quality and low price products. Aligning ourselves with customers in the same vision of providing superior quality, has contributed to our success. Also honesty is our best policy.

FAQ

FREQUENTLY ASKED QUESTIONS

What is your main products?

A: Our main products are sheet metal parts, chassis, cabinet, deep drawn parts, stamping parts and CNC machined parts.

How to ensure that every process’s quality?

A: Every process will be checked by our quality inspection department which insures every product’s quality. In the production of products, we will personally go to the factory to check the quality of products.

How long is your delivery time?

A: Our delivery time is generally 15 to 25 days. Or according to the quantity.

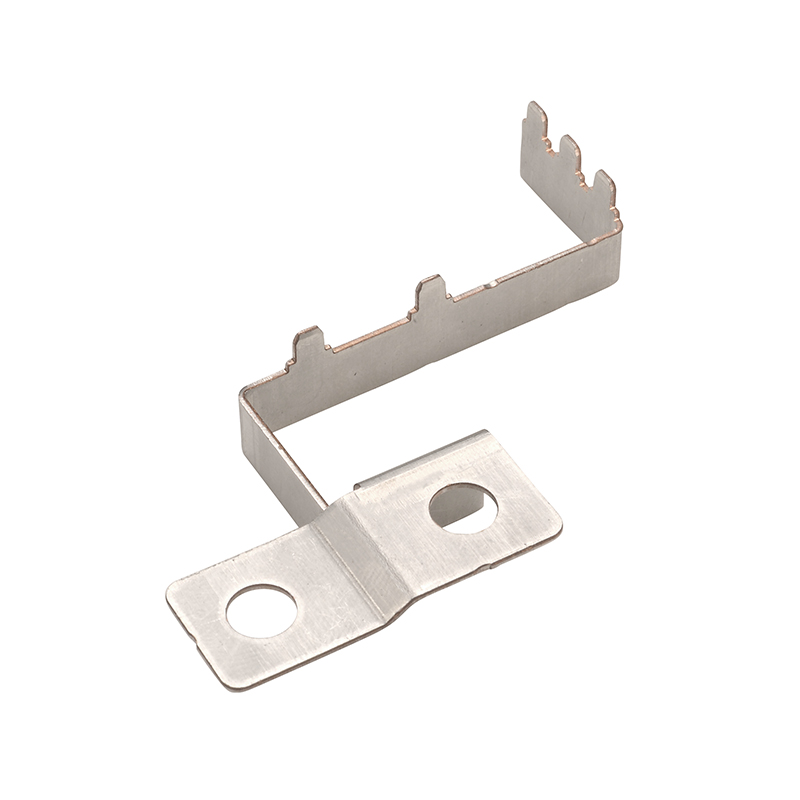

Product detail pictures:

Related Product Guide:

We emphasize progress and introduce new solutions into the market each year for Factory source Nickel Plating Process Flow Chart - Customized Precision Aluminum CNC Turning Parts Anodized CNC Machining Part – Mingxing, The product will supply to all over the world, such as: New Orleans, Marseille, Russia, There are advanced producing & processing equipment and skilled workers to ensure the merchandise with high quality. We've got found an excellent before-sale, sale, after-sale service to ensure the customers that could rest assured to make orders. Until now our merchandise are now moving on fast and very popular in South America, East Asia, the Middle east, Africa, etc.

Hope that the company could stick to the enterprise spirit of Quality, Efficiency, Innovation and Integrity, it will be better and better in the future.

-

Leading Manufacturer for Zinc Plating - Custom...

-

Factory Price For All Metal Stamping - Aluminu...

-

China Factory for Impressart Metal Stamping Kit...

-

Good Quality Anodizing - Aluminum heat sink fo...

-

Hot-selling Nickel Plating - Flexible Nickel P...

-

Fast delivery Kenmode Precision Metal Stamping ...