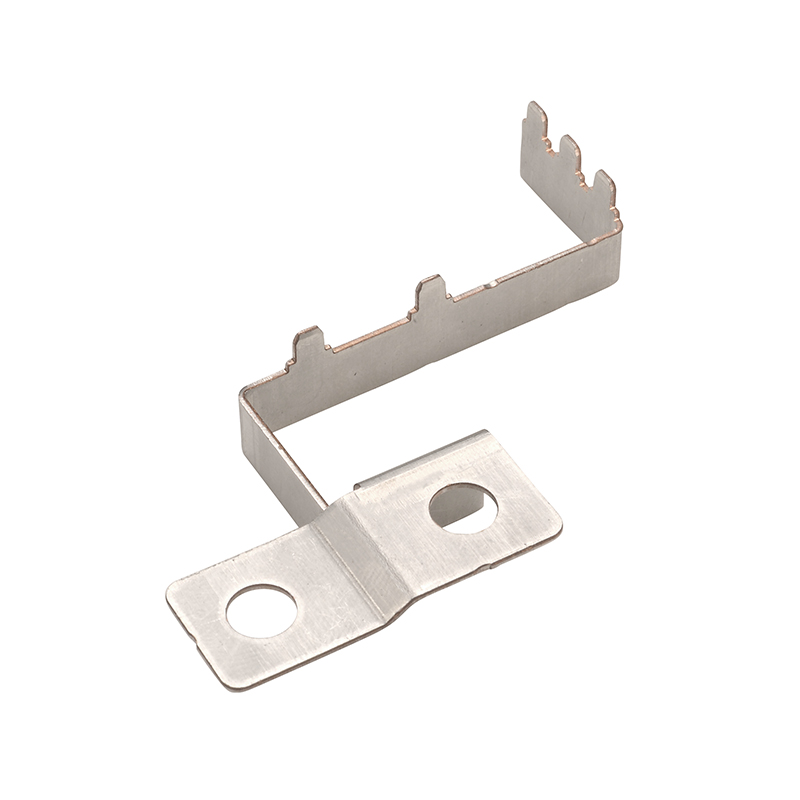

Factory making Hydrogen Embrittlement Zinc Plating - Flexible Nickel Plated Busbars Copper Busbars – Mingxing Detail:

Product Description

|

Material available |

C1100, T2, Bronze, brass, copper alloy, aluminum alloy, tin plated, nickel silver |

|

Surface treatment |

zinc/nickel/chrome/tin plating(colour or natural), Galvanization, anodizing, oil spraying, powder coating, polishing, passivate, brush, wire drawing, painting, etc. |

|

Metal processing available |

Tooling making, Prototype, Cutting, Stamping, Welding, Tapping, Bending and Forming, Machining, Surface treatment, Assembly |

|

Specification |

OEM/ODM, as per client’ s drawing or sample |

|

Certificate |

ISO9001:2015/IATF 16949/SGS/RoHS |

|

Tolerance |

0.02mm-0.1mm |

|

Software |

Auto CAD, Soliworks, PDF |

|

Application |

automotive parts, railroad parts,medical parts, marine parts, lighting parts, pump body, valve parts,architectural parts and furniture parts, etc. |

Features

1. End slots can be used to fix busbar to a support or connect the main input conductor

2. Heavy-duty power connection

3. Circuit breaker, generator and prefabricated power network conductor

4. Alternative to large and multiple cables

5. Earth/ground connection

6. Power distribution

7. Rounded edges

Why choose us?

At Mingxing, our capabilities for custom copper busbars includes:

1. RoHS Compliance

2. Barrel and Rack Plating

3. Material Selection Suggestion

4. Progressive Die Stamping

5. Just-in-Time Delivery

6. Design and Assembly

7. Prototyping Services

FAQ

FREQUENTLY ASKED QUESTIONS

Q: Are you a factory or trading company?

A: We are a factory which has been producing metal stamping parts for more than 25 years.

Q: What are your main products?

A: We specialize in manufacturing metal stamping die and metal stamping parts. And the products is used for circuit breaker, converter, delay, outlet wall switch and socket etc.

Q: Can I get the samples?

A: Yes, sample order is available for quality check and market test, and it will be freight collect payment. If simple sample, we will not charge cost; If OEM/ODM samples, we will charge for the sample cost.

Q:What’s the delivery time?

A:The standard stamping parts is 3~7days after payment. If OEM or make the mould, we will confirm the delivery time with you.

Product detail pictures:

Related Product Guide:

We attempt for excellence, support the customers, hopes to become the top cooperation team and dominator enterprise for staff, suppliers and shoppers, realizes worth share and continual marketing for Factory making Hydrogen Embrittlement Zinc Plating - Flexible Nickel Plated Busbars Copper Busbars – Mingxing, The product will supply to all over the world, such as: Qatar, Mexico, Serbia, With good quality, reasonable price and sincere service, we enjoy a good reputation. Products are exported to South America, Australia, Southeast Asia and so on. Warmly welcome customers at home and abroad to cooperate with us for the brilliant future.

High production efficiency and good product quality, fast delivery and completed after-sale protection, a right choice, a best choice.

-

Factory directly Zinc Plating Color Chart - Ba...

-

Hot-selling Precision Metal Stamping Companies ...

-

Wholesale Price China Deutsch Connector - Cust...

-

Personlized Products Heat Sink Paste - Stainle...

-

Wholesale Price China Deutsch Connector - OEM/...

-

Factory directly Chipset Heat Sink Not Detected...