Description

|

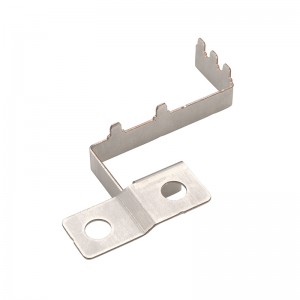

Property |

Specification |

| Material | T2 copper (or T1, T3, TU1, TU2 etc.) |

| Conductivity | > 100 IACS |

| Busbar Thickness | 1mm, 2mm, 3mm or other |

| Length | Up to 3m |

| Other Dimension | As confirmed by drawing |

| Plating | Tin/nickel/silver/others |

| Insulation | Heat shrink sleeve/PVC dip/bare copper |

| Warranty | 20 years |

| Certificate | ISO9001&IATF16946 |

| Main Process | Cut, punch, stamp, drill, twist, test |

| Delivery | 5-7 days |

| MOQ | 1 piece |

| OEM | Custom all types of bus bars |

| Application | Electric vehicle battery, power distribution equipment |

Custom made nickel plated copper busbar features

1.Excellent electrical conductivity

2.High bonding strength

3.Made of pure T2 copper

4.Copper foil busbar designed for use in transformers, allowing for thermal expansion and contraction

5.Maximum flexibility and reduced vibration due to use of copper foil. Typically used for copper busbar systems, transformer connections, and high voltage switchgear.

Q. Are you a factory or a trade company?

A:We're a factory with over 20 years experience in the heat sink field.It is a enterprise that professionally design and produce Heat sinks, electronic components, auto parts and other stamping products.

Q. How to get a quotation?

A: Please send us info such as drawing,material surface finish,quantity.

Q. What about the lead time?

A: Average for 12 working days, open mould for 7 days and mass production for 10 days

Q. Do the products of all the colors are the same with same surface treatment?

A: No. about powder coating, the bright-color will higher than white or gray. About the Anodizing, colorful will higher than silver, and black higher than colorful.