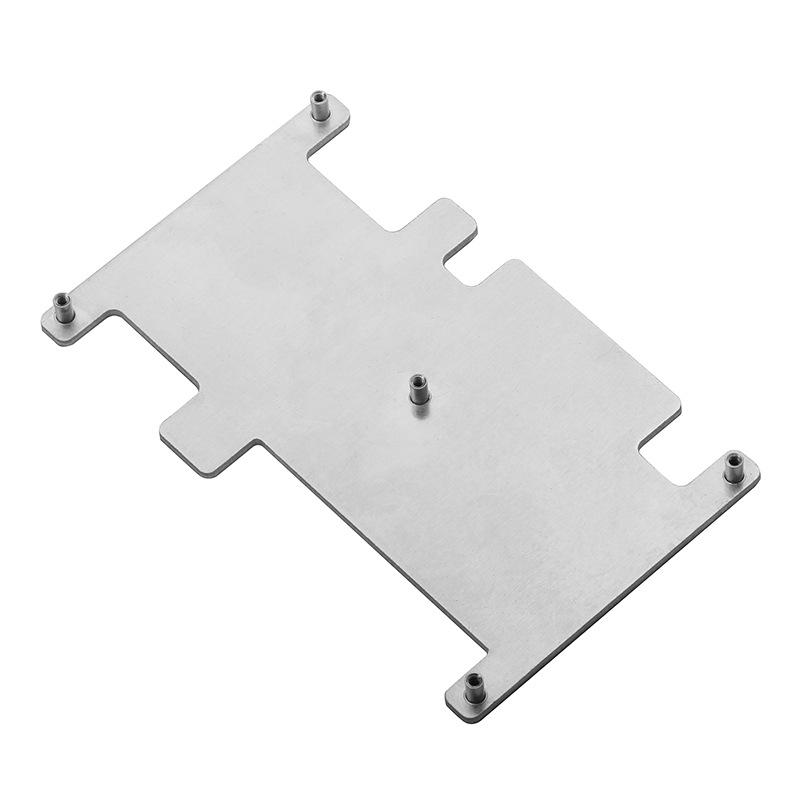

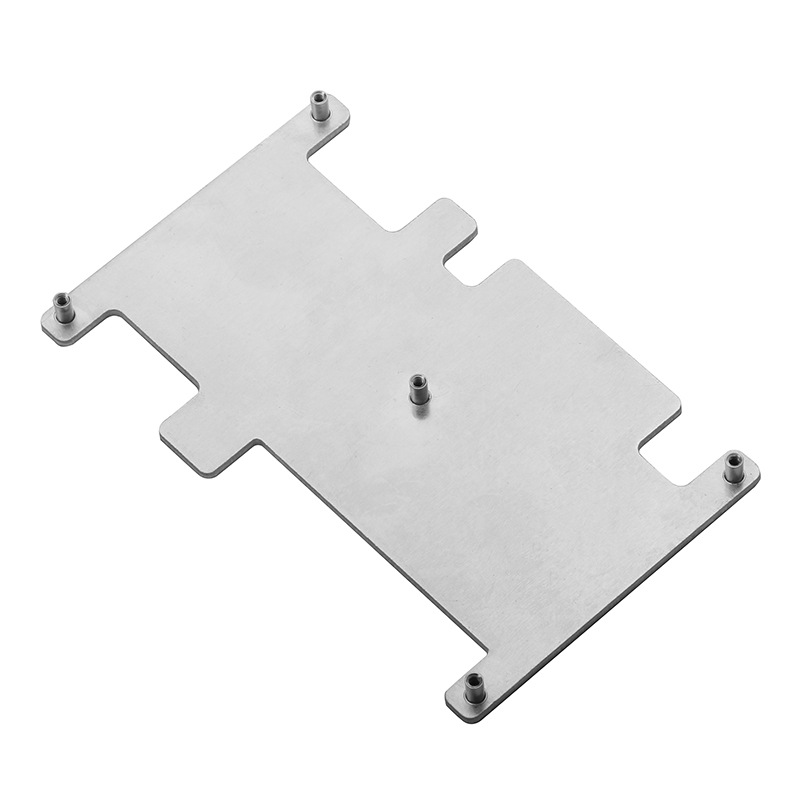

Competitive Price for Immersion Tin Plating - Precision Sheet Metal Fabrication Aluminum Bending Stamping Parts Mount Bracket – Mingxing Detail:

Product Description

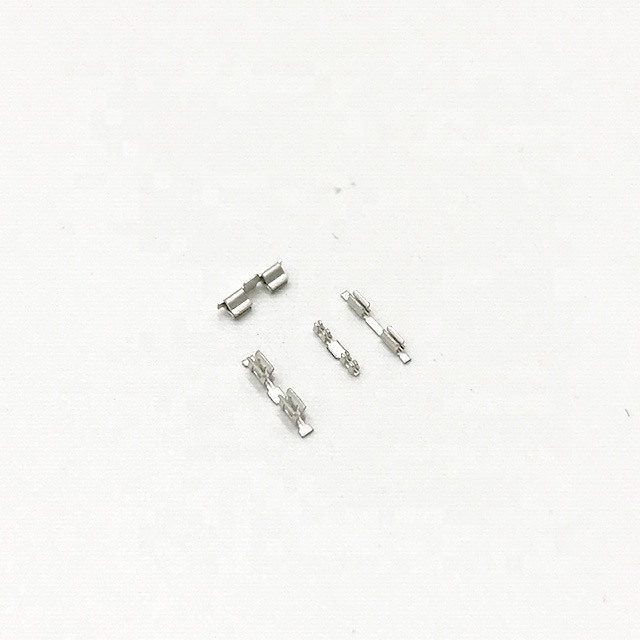

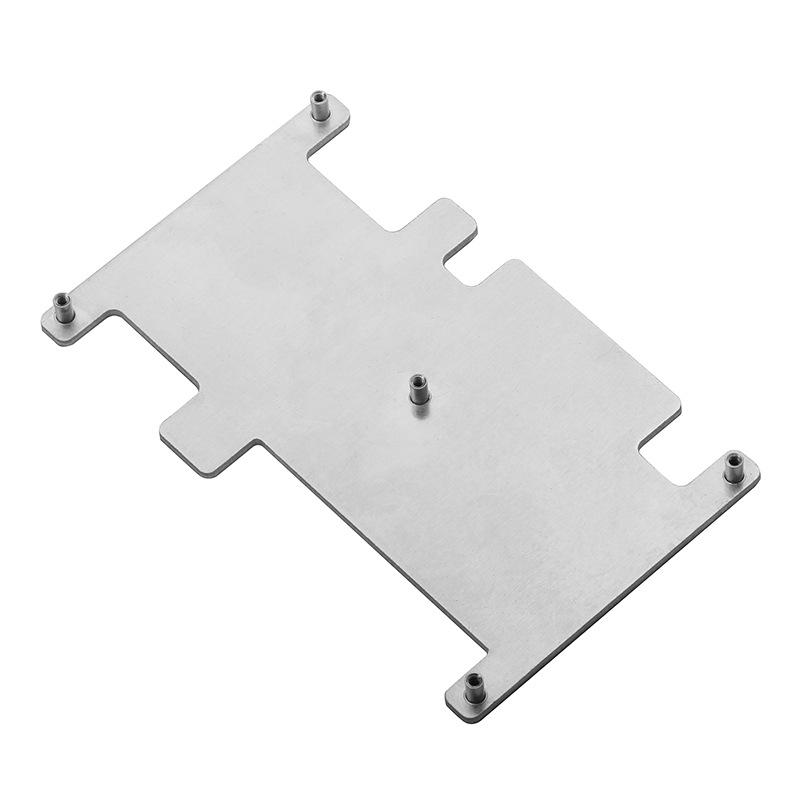

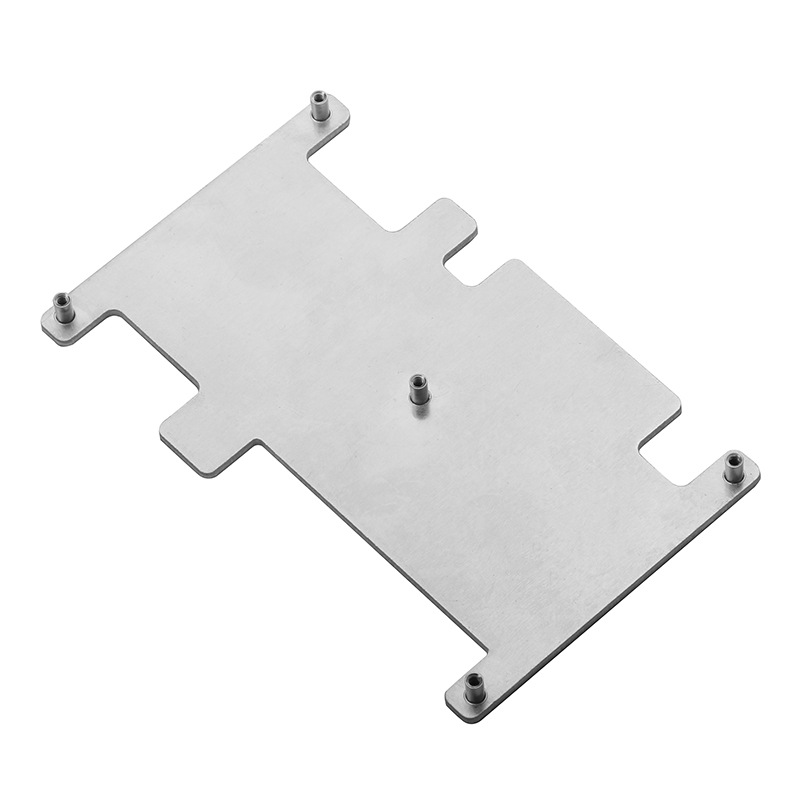

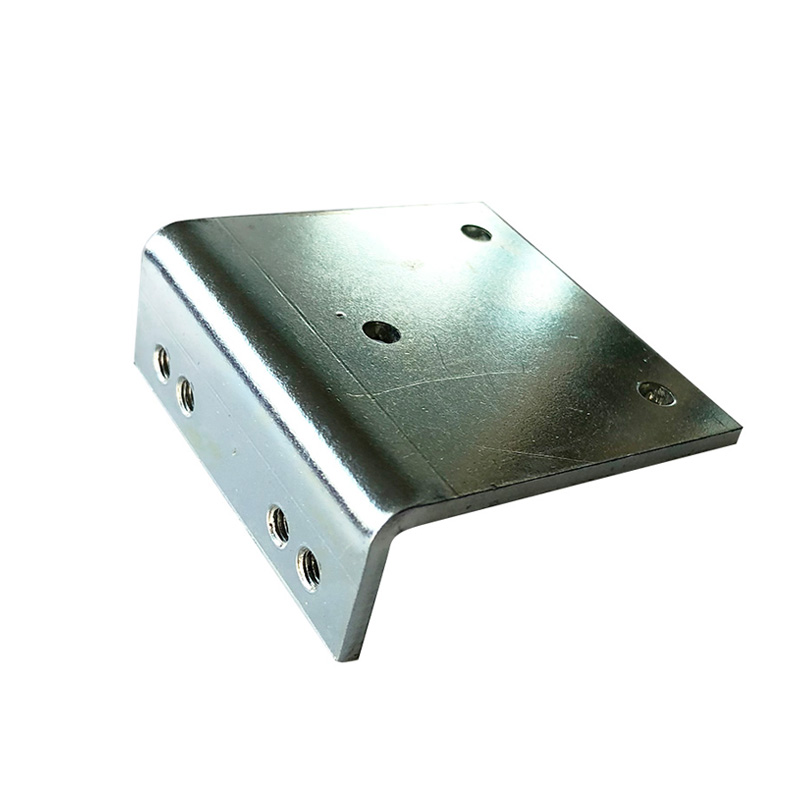

| Material | Precision Sheet Metal Fabrication Aluminum Bending Stamping Parts Mount Bracket |

| Surface treatment | Carbon steel, SPCC, SGCC, Stainless steel, Aluminum, Brass, Copper, etc. |

| Process | Tooling making, Prototype, Cutting, Stamping, Welding, Tapping, Bending and Forming, Machining, Surface treatment, Assembly |

| Specification | OEM/ODM, as per client’ s drawing or sample |

| Certificate | ISO9001:2015/IATF 16949/SGS/RoHS |

| MOQ | 1000pcs |

| Software | Auto CAD, 3D(STP, IGS, DFX), PDF |

| Application | Automoblies, chassis equipment, furniture accessories, electronic components |

Custom Metal Brackets Capabilities

Our company is IATF-certified and ISO 9001-certified, you can be assured to rely on the safety and quality of the stamped products we produce. We design the brackets strictly as customer’s requirement by CAD and inspected by 24h salt spray test and projector. The manufacturing processes we can be used include stamping, bending, laser cutting, blanking, drilling, lathe and mill, etc.

Our Advantages

1.Professional in producing OEM parts: metal stamped, machined, deep drawn and sheet metal fabricated parts with different surface finishing.

2.20+ years of experience in the metal products processing area and advanced processing machines in saving materials;

3.Reply in time: Reply within 2 hours, TM reply within 30 minutes.

4.100% QC quality inspection before delivery.

5.Delivery on time: two shifts in production.

FAQ

FREQUENTLY ASKED QUESTIONS

Q. Are you a factory or a trade company?

A:We’re a factory with over 20 years experience in the heat sink field.It is a enterprise that professionally design and produce Heat sinks, electronic components, auto parts and other stamping products.

Q. How to get a quotation?

A: Please send us info such as drawing,material surface finish,quantity.

Q. What about the lead time?

A: Average for 12 working days, open mould for 7 days and mass production for 10 days

Q. Do the products of all the colors are the same with same surface treatment?

A: No. about powder coating, the bright-color will higher than white or gray. About the Anodizing, colorful will higher than silver, and black higher than colorful.

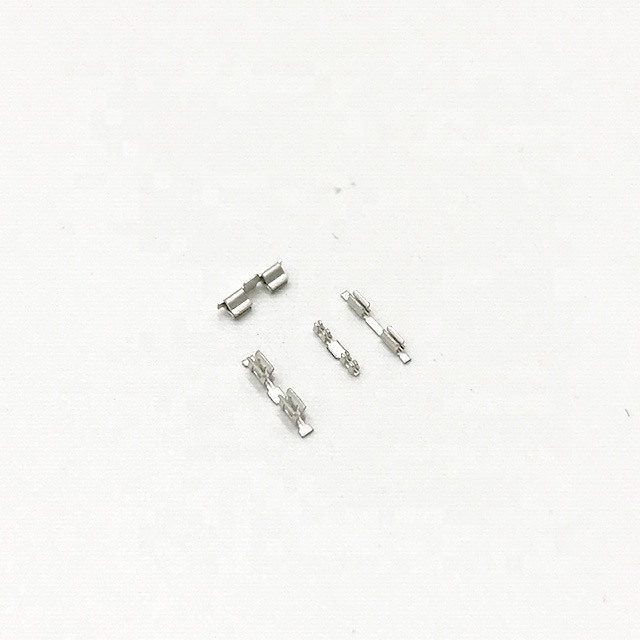

Product detail pictures:

Related Product Guide:

Our business puts emphasis over the administration, the introduction of talented staff, plus the construction of team building, attempting hard to boost the standard and liability consciousness of personnel customers. Our corporation successfully attained IS9001 Certification and European CE Certification of Competitive Price for Immersion Tin Plating - Precision Sheet Metal Fabrication Aluminum Bending Stamping Parts Mount Bracket – Mingxing, The product will supply to all over the world, such as: Cannes, Sydney, Tajikistan, When you are keen on any of our goods following you view our product list, be sure to feel free to make contact with us for inquiries. You'll be able to send us emails and get in touch with us for consultation and we shall respond to you as soon as we're able to. If it's convenient, you could find out our address in our web site and come to our enterprise. or additional information of our products by yourself. We're generally ready to build lengthy and steady co-operation relations with any possible shoppers within the associated fields.

We are old friends, the company's product quality has been always very good and this time the price is also very cheap.

-

Factory making Copper Busbar Weight Calculation...

-

Low MOQ for Automotive Stamping Dies - Custom ...

-

Hot sale Factory Copper Busbar Ampacity - Alum...

-

Good User Reputation for Metal Stamping For Aut...

-

2022 New Style Metal Stamping Process - OEM Me...

-

Original Factory Zinc Plating At Home - OEM Hi...