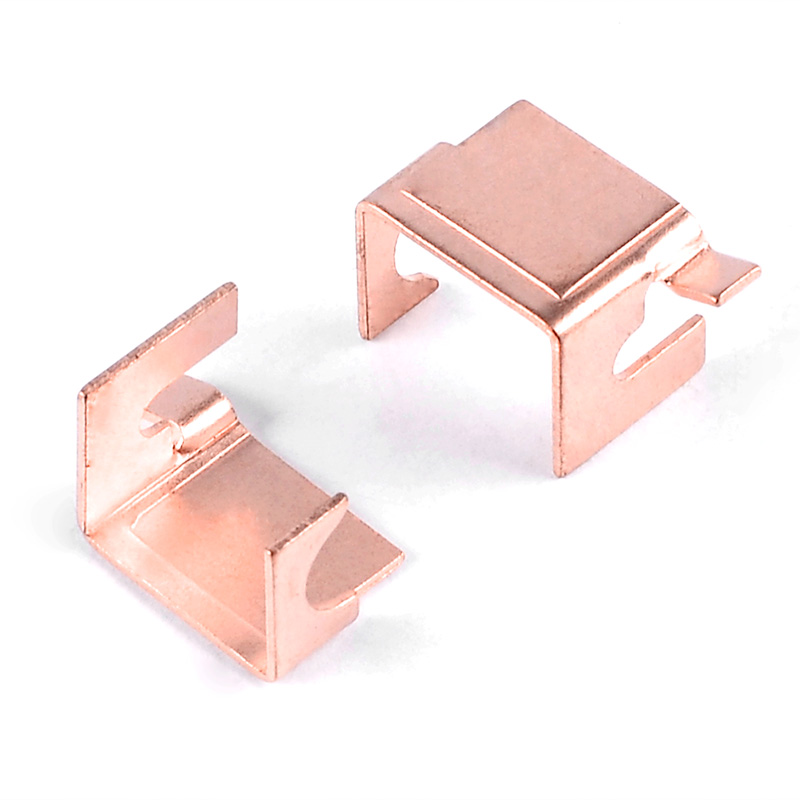

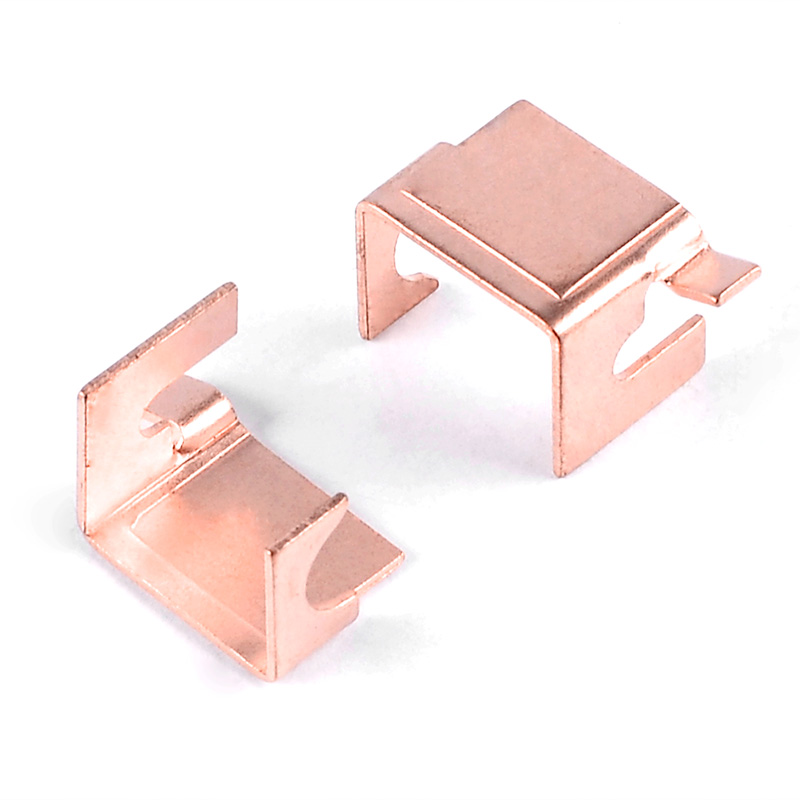

China wholesale Copper Flexible Busbar - Metal fabrication bending parts service custom metal stamping – Mingxing Detail:

Products Description

| Material | Stainelss steel 304 , 316 , 202 , 201 ,430 . Aluminum 6061 , 6062 ,5052 , Brass , Copper , Cold Rolled Steel , Hot Rolled Steel |

| Size Range | Min 3.0 X 3.0 mm , Max 1000 X 2000 mm |

|

Dimensions |

As client’s requirement |

| Thickness | 0.4–20.0 mm |

| Surface Treatment | Powder coating ,Painting ,Shot blasting, Polsihing ,Electrical galvanizing, Chemical galvanizing, Chrome plating , Nickel Plating, Tumbling, Passivation etc. |

| Machining | Stamping machine for 6.3 Tons to 160 Tons . |

| Support Software | Pro-E , UGS , SolidWorks ,AutoCAD |

| Quality Control | Chemical analysis, mechanical properties, impact testing, pressure testing, 3-D co-ordinate CMC, metallography, magnetic particle flaw inspection, etc. |

| MOQ | 1000pcs |

| Package | Carton and Pallet , exact part with package every pc |

Quality Control

1) Checking the raw material after they reach our factory——- Incoming quality control ( IQC)

2) Checking the details before the production line operated

3) Have full inspection and routing inspection during mass production—In process quality control(IPQC)

4) Checking the goods after they are finished—- Final quality control(FQC)

5) Checking the goods after they are finished—–Outgoing quality control(OQC)

FAQ

FREQUENTLY ASKED QUESTIONS

Q1: Are you a direct manufacturer?

A:Yes,we are direct manufacturer.We have been in this domain since 2005. And if you want, we could chatting with you on video via Wechat/Whatsapp/Messenger and any way you like to show you our plant.

Q2: How can you guarantee quality?

A: Always a pre-production sample before mass production;

Always 100% inspection before shipment;

Q3: What kind of service/products you provide?

A: Service of OEM/ one-stopservice/ assembly; From mold design, mold making, machining, fabrication, welding, surface, treatment, assembly, packing to shipping.

Product detail pictures:

Related Product Guide:

We now have a skilled, performance team to supply good quality services for our consumer. We often follow the tenet of customer-oriented, details-focused for China wholesale Copper Flexible Busbar - Metal fabrication bending parts service custom metal stamping – Mingxing, The product will supply to all over the world, such as: Serbia, United States, Nicaragua, The president and all the company members would like to provide qualified goods and services for customers and sincerely welcome and cooperate with all native and foreign customers for a bright future.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.

-

2022 wholesale price Progressive Stamping Die D...

-

China Factory for Impressart Metal Stamping Kit...

-

Factory Free sample Electroless Nickel Plating ...

-

Manufacturer for Anodizing Near Me - Lithium B...

-

Fast delivery Nickel - Customized Metal Stampi...

-

China wholesale Zinc Gold Plating - OEM Stainl...