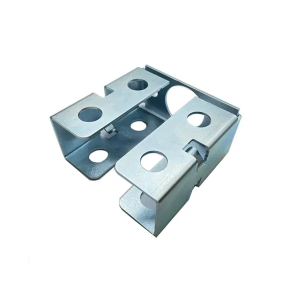

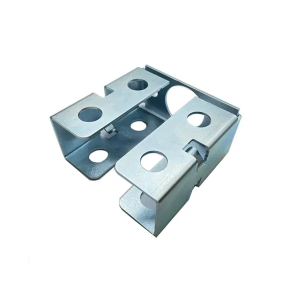

Product Description

| Material | Steel, Stainless steel, Aluminum, Spring steel, SK7, 65MN, SPCC, SGCC |

| Surface treatment | nickel/chrome/tin plating(colour or natural), Galvanization, polishing, etc. |

| Process | Metal stamping, Cutting / Punching / Bending / Welding / Deep Drawing; |

| MOQ | 1000pcs |

| Software | Auto CAD, 3D(STP, IGS, DFX), PDF |

| Application | Automoblies, chassis equipment, furniture accessories, electronic components |

Custom Metal Stamped Clips Capabilities

No matter you need a single prototype or 5,000,000 parts, Mingxing’ ISO 9001 and IATF 16949 certified facilities can produce the perfect custom clip to meet your demands. Mingxing offers all the latest technological innovations like CAD/CAM, CNC machines, and full team of experienced tool and die makers in the industry. In addition, we collect data across all manufacturing stages to facilitate final inspection before delivery, which means you get the highest levels of quality available.

Our Service

1. Offer free samples.

2. Welcome OEM/ODM.

3. Provide proper suggestions or solutions.

4. Offer multiple secondary operations such as reaming, drilling, heat treating, plating, painting etc.

5. Assembly well by welding, installation, paste stickers and customized package.

Q. Are you a factory or a trade company?

A:We're a factory with over 20 years experience in the heat sink field.It is a enterprise that professionally design and produce Heat sinks, electronic components, auto parts and other stamping products.

Q. How to get a quotation?

A: Please send us info such as drawing,material surface finish,quantity.

Q. What about the lead time?

A: Average for 12 working days, open mould for 7 days and mass production for 10 days

Q. Do the products of all the colors are the same with same surface treatment?

A: No. about powder coating, the bright-color will higher than white or gray. About the Anodizing, colorful will higher than silver, and black higher than colorful.

-

Customized Sheet Metal Fabrication Stamping Ser...

-

Custom OEM Aluminum Copper Stamping Heat Sink P...

-

Custom Tin Plated SMT Splice Clips Shielding Clips

-

Factory OEM Metal Stamping Parts Aluminum Steel...

-

ISO-Certified Manufacturer of Carbon Steel Shee...

-

Pcb Electronics EMI Shield Frame Custom EMI/RF ...